1.2601 Steel Description

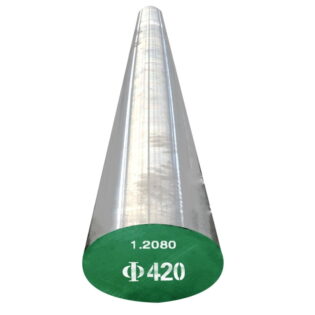

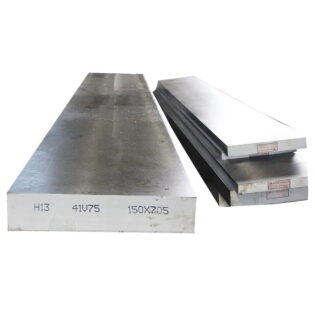

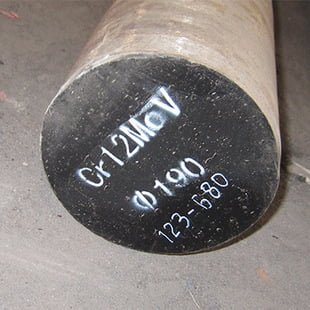

We supply in Round bar, gauge plate steel, pipe/Tube,rod, square, hexagonal, blanks, plate, sheet, precision ground flat bar, precision ground bar stock and hollow bar. provide black surface and black surface alloy steel material.

1.2601 is a German Cold work tool alloy steel material grade.it is shock resisting steel. it belong to DIN 17350 standard.

Digital Grade material number 1.2601. Metal Steel Grade W-Nr X165CrMoV12 It is a die steel, use in extrusion moulds, Hot Cast moulds. like aluminium production, Aluminium cutting mold. Our Tool Steel material 100% ultrasonic tested with good price.

Small size steel products make by hot rolled, large size steel products make by forging. 1.2601 with X165CrMoV12 is equivalent Belong to W-Nr and DIN.

Mechanical properties of Alloy Steel X165CrMoV12 | 1.2601

Hardness: Annealing 225 HB max, Q+T: 58-63 HRc, different hardness according different Tempering temperature.

- Yield strength:

Heat treatment of X165CrMoV12 | 1.2601 Cold work tool steel

- Annealing: Annealing temperature/°C: 800~830; After the annealing, degree of hardness ≤HBS: 255

- Quenching: Hardening temperature/°C: 980~1010, Quenching in oil or air

- Tempering: Commonly used drawing temperature/°C: 180~250; After tempering hardness HRC | 100°C: 63; After tempering hardness HRC | 200°C: 61; After tempering hardness HRC | 300°C: 60 ; After tempering hardness HRC | 400°C: 58

- Normalizing: at Normalizing temperature, then cool in furnace

1.2601 Cold Work Tool Steel Details

DIN 1.2601 is a Cold work tool alloy steel material grade.it is shock resisting steel. Digital Grade material number 1.2601 use in extrusion moulds, Hot Cast moulds. like aluminium production, Aluminium cutting mold. Our Tool Steel material 100 % ultrasonic tested with good price. Small size steel products make by hot rolled, large size steel products make by forging. 1.2601 with is equivalent Belong to DIN.

Equivalent

| Country | China | Japan | Germany | USA | UK |

| Standard | GB/T 1299 | JIS G4404 | DIN EN ISO4957 | ASTM A681 | BS 4659 |

| Grade | Cr12MoV | SKD11 | 1.2601 | D5 |

Chemical Composition

| Grade | C | Mn | P | S | Si | W | V | Cr | ||||||

| DIN 1.2601 | 1.55 | 1.75 | 0.20 | 0.40 | 0.03 | 0.03 | 0.25 | 0.40 | 0.40 | 0.6. | 0.1 | 0.50 | 11.0 | 12.0 |

Mechanical Properties

| Grade | Tensile strength | Yield strength | Elongation | Reduction | Impact Value | Hardness |

| DIN 1.2601 | 488 (≥)MPa | 12% | 31% | 31J | Annealing 225 HB max, Q+T: 58-63 HRc |

Overviews

| Size | Round | Dia 6-1200mm |

| Plate/Flat/Block | Thickness 6mm-500mm | |

| Width 20mm-1000mm | ||

| Process | EAF+LF+VD+Forged+Heat treatment(optional) | |

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | |

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | |

| Delivery condition | Forged; Hot rolled; Cold drawn | |

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | |

| Payment terms | T/T;L/C;/Money gram/ Paypal | |

| Trade terms | FOB; CIF; C&F; etc.. | |

| Packing | Standard Packages, or as Customers Request | |

| Delivery time | 30-45 days | |

| Application | DIN 1.2601 is suitable for applications High alloyed CrMoV steel for cutting tool and cold work tool steel. | |

Heat treatment

Annealing:

Temperature/°C: 800~830; After the annealing, degree of hardness ≤HBS: 255

Quenching:

Hardening temperature/°C: 980~1010, Quenching in oil or air

Tempering:

Commonly used drawing temperature/°C: 180~250;

(1) After tempering hardness HRC | 100°C : 63;

(2) After tempering hardness HRC | 200°C : 61; After tempering hardness HRC | 300°C : 60 ;

(3) After tempering hardness HRC | 400°C : 58

Normalizing

At Normalizing temperature, then cool in furnace

Delivery condition

(1) For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

(2) For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

(3) For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.