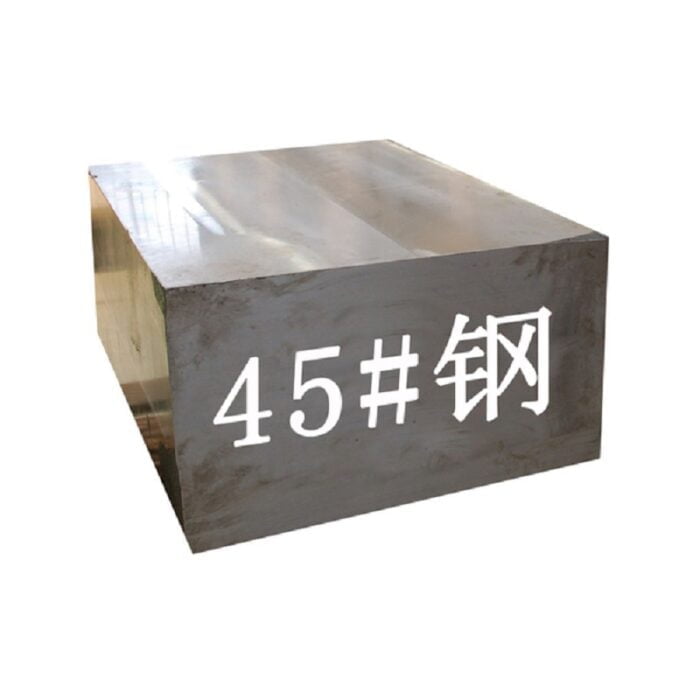

S45C Steel Description

S45C is a kind of high quality carbon structural steel, corresponding to Chinese standard 45#, American standard: 1045, German standard C45.It is characterized by higher strength and deformation resistance than ordinary A3 steel.

- Chinese name: 45 steel plate

- Foreign Name: Carbon Steel

- Sigma b \ Mpa: p. 600

- Sigma s \ Mpa: p. 355

- The delta \ % 5:16 or higher

- Common thickness: 0.5-80 MM

- Material density: 7.85g/cm³

- GB number: GB/T 699-1999

S45C Steel Introduce

S45C steel grade is a very common engineering steel materials. In this post, you can check the thorough technical and properties of machine structural S45C carbon steel.

Available Forms in Market: Following are the available forms of S45C steels in the global market:

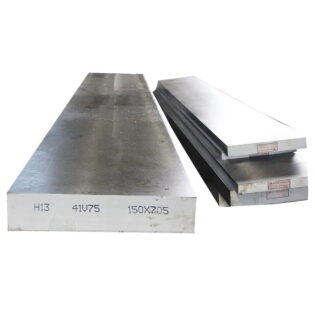

- Plates

- Hexagonal bars

- Blocks

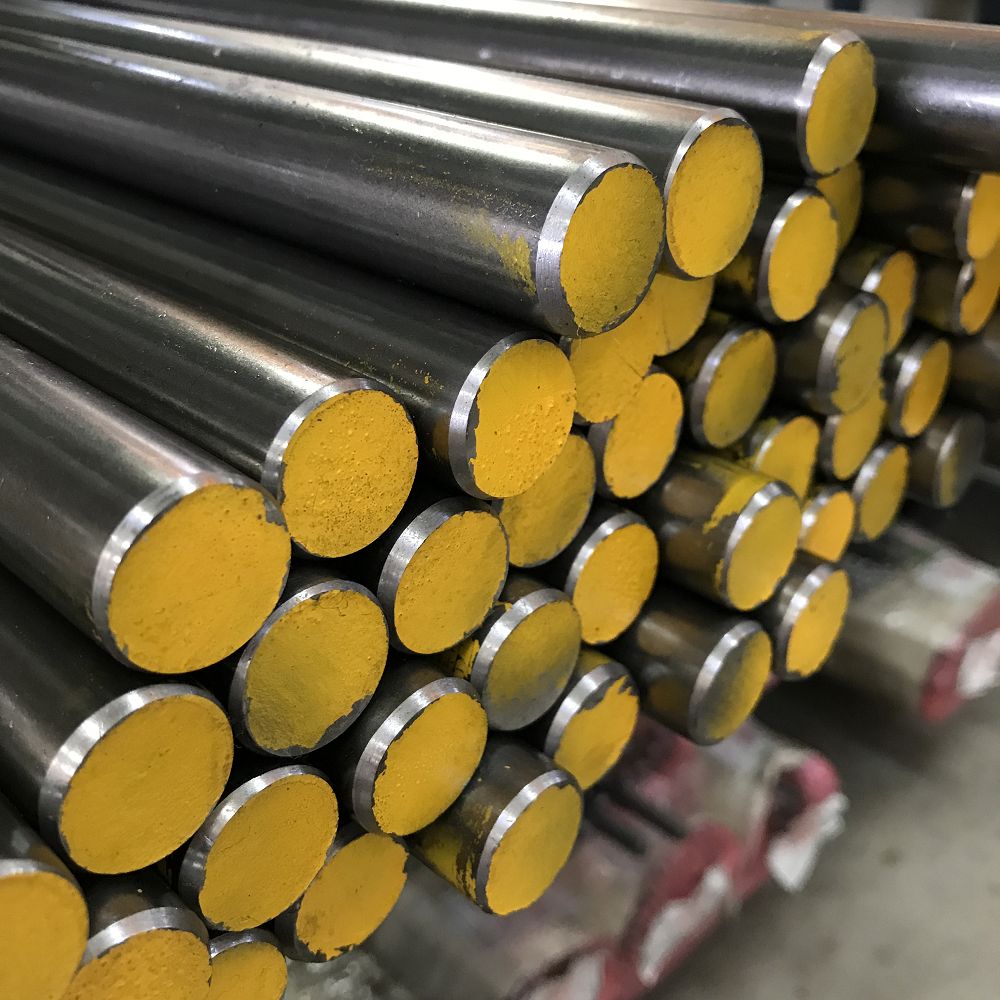

- Round bars

- Square bars

- Sheets

Surface finish is furnished in turned, rough machined, and black chromed. This should be confirmed from suppliers.

Dimensional Characteristics of S45C Steels: The applicable thickness for this C45 material as obtained by online statistics in the market starts from 10 mm to 1500 mm defending upon processes. However the width of this material varies and it is available in 200 mm to 3000 mm.

As it is available in different forms, dimensional aspects should be confirmed from suppliers, manufacturers and dealers. C45 round bars diameters starts from 8 to 300 millimeters.

S45C Steels belongs to JIS G4051

S45C Steel Grade is one steel grade material in JIS G4051. which is standard specification of carbon steels for machine structural use. Specifically, this is standard for heat treatable steels, alloy steels and free cutting steels.

Common Available Shapes

JIS S45C Steel is a medium strength steel. Suitable for shafts studs, keys etc. Available as rolled or normalised.

JIS S45C machinery steel are usually supplied as square bar, or round bar or flat.

JIS Steel S45C is excelling in weldability & machinability , and S45C steels can be subjected to various heat treatments.

Grade Steel Equivalents

There are some other structural steel standards and steel grades similar and equivalent to JIS S45C Steel Grade, as shown below:

- DIN C45, CK45, 1.1191

- AISI 1045

- EN-8 / BS 970-1955 080M40

Steel Properties

Chemical Composition

| Standard | Grade | C | Mn | P | S | Si |

| JIS G4051 | S45C | 0.42-0.48 | 0.60-0.90 | 0.03 | 0.035 | 0.15-0.35 |

JIS Spec S45C Steels Mechanical Properties

- Density (kg/m3) 7700-8030

- Young’s Modulus (GPa) 190-210

- Tensile Strength (Mpa) 569 (Standard) 686 (Quenching, Tempering)

- Yield Strength (Mpa) 343 (Standard) 490 (Quenching, Tempering)

- Poisson’s ratio 0.27-0.30

JIS S45C Material Hardness

- Brinell Hardness (HB) 160-220 (Annealed)

Heat Treatment

JIS Steel Grade S45C Steel Materials are applicable for the respective heat treatment operations.

- Full Annealing 800 – 850°C

- Normalising 840 – 880°C

- Hardening 820 – 860°C

- Quenching medium Water or Oil

- Tempering 550 – 660°C

- Melting point of S45C is ~1520 Degree Celsius

Application of Steel Materials

- Manufacturing material of shafts and Axles

- Manufacturing material of Knives and paint scrapers

- Manufacturing material of Studs and Spindles

- Parts used in Automotive industry

- Parts in different engineering applications

- Used in the manufacturing of different gears

Following are some of the mechanical properties in normalized

- The proof stress of the subject steel is expressed in Newton per millimeters and it must be at-least 275-390 N/mm2 (MPa).

- The elongation property of C45 steel varies with the heat treatment process and thickness but it is indicated typically 14-16%.

- The tensile strength of the subject steel is expressed in Newton per millimeters and it must be at-least 305-620 N/mm2 (MPa).

JIS S45C grade carbon steel is widely used in machinery manufacturing, good mechanical properties of this steel. But S45C Grade Steel is a medium carbon steel, hardened performance is not good, 45 steel can be hardened to HRC42 ~ 46.

So if you need to surface hardness, but also hopes to play steel superior mechanical properties, often steel surface carburizing, so you can get the required surface hardness.Mainly used for a variety of motor shaft, automotive parts.