C45 Steel Bar Description

C45(1.0503) is a kind of medium carbon high quality steel with high strength. Because of its poor hardenability, it is generally used in the normalizing state.

When the mechanical properties are required to be high, it is treated by tempering and tempering. Cold deformation plasticity medium, annealing and normalizing cutting machinability is better than the quality. It is used to manufacture high strength parts, such as gears, shafts, piston pins, and mechanical processing parts, forgings, stamping parts, bolts, nuts and pipe joints.

Executive standard :EN 10083/2-1991

Corresponding domestic brand number: 45#

Corresponding Japanese brand number: S45C

Corresponding British grades: 060A47,080A47,080M46

The corresponding French brand number is XC45

Steel C45 Round Bar is an unalloyed medium carbon steel, which is also a general carbon engineering steel.

C45 is a medium strength steel with good machinability and excellent tensile properties.

C45 round steel is generally supplied in the black hot rolled or occasionally in the normalised condition, with a typical tensile strength range 570 – 700 Mpa and Brinell hardness range 170 – 210 in either condition.

It does not however respond satisfactorily to nitriding due to a lack of suitable alloying elements.

C45 round bar steel is equivalent to EN8 or 080M40. Steel C45 bar or plate is suitable for the manufacture of parts such as gears, bolts, general-purpose axles and shafts, keys and studs.

Supply Range of Steel C45 Round Bar

- Round Bar: diameter 8mm – 3000mm

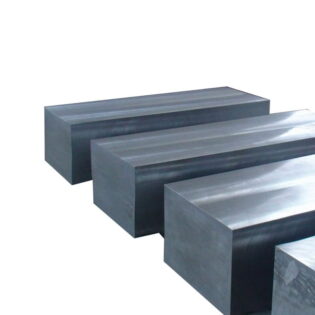

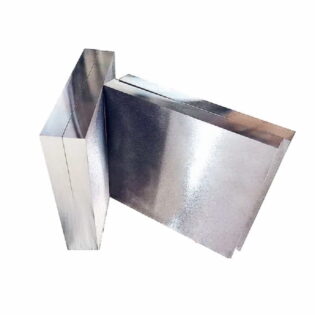

- Steel Plate: thickness 10mm – 1500mm x width 200mm – 3000mm

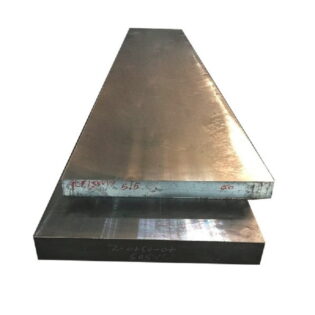

- Flat Bar: 200mm – 1000mm

- Square Steel: 20mm-800mm

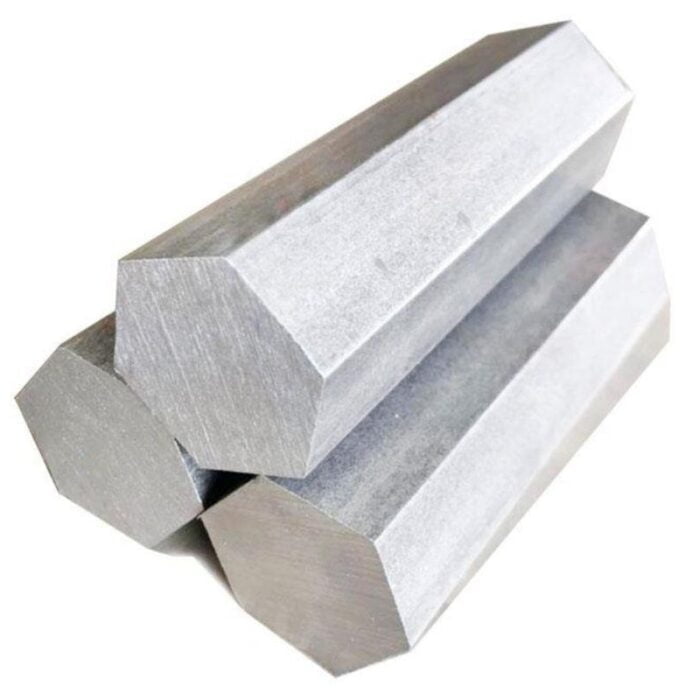

- Hexagon Steel.

Surface Finish: Black, Rough Machined, Turned or as per given requirements.

Bar[/caption]

Bar[/caption]

Common Specifications

| Country | US | British | Japan | Australia |

| Standard | ASTM A29 | EN 10083-2 | JIS G4051 | AS 1442 |

| Grades | 1045 | C45/1.1191 | S45C | 1045 |

Composition Properties

| Standard | Grade | C | Mn | P | S | Si | Ni | Cr |

| ASTM A29 | 1045 | 0.43-0.50 | 0.60-0.90 | 0.04 | 0.050 | |||

| EN 10083-2 | C45/1.1191 | 0.42-0.50 | 0.50-0.80 | 0.03 | 0.035 | 0.4 | 0.4 | 0.4 |

| JIS G4051 | S45C | 0.42-0.48 | 0.60-0.90 | 0.03 | 0.035 | 0.15-0.35 |

Mechanical Properties

- Mechanical Properties in Quenched+Tempered Condition

| Diameter d (mm) | Thickness t (mm) | 0.2 % proof stress (N/mm2) | Tensile strength (N/mm2) | Elongation A5 (%) | Reduction Z (%) |

| <16 | <8 | min. 490 | 700-850 | min. 14 | min. 35 |

| <17-40 | <8<=20 | min. 430 | 650-800 | min. 16 | min. 40 |

| <41-100 | <20<=60 | min. 370 | 630-780 | min. 17 | min. 45 |

- Mechanical Properties in Normalized Condition

| Diameter d (mm) | Thickness t (mm) | 0.2 % proof stress (N/mm2) | Tensile strength (N/mm2) | Elongation A5(%) | |

| <16 | <16 | min. 390 | min. 620 | min. 14 | |

| <17-100 | <16<=100 | min. 305 | min. 305 | min. 16 | |

| <101-250 | <100<250 | min. 275 | min. 560 | min. 16 |

Forging of Carbon Steel Round Bar

Hot forming temperature: 850-1200°C.

Pre heat to 750°C – 800°C, then continue heating to 1100°C – 1200°C maximum, hold until temperature is uniform throughout the section and commence forging immediately. Forging is not workable below 850°C. Finished forgings could be air cooled.

Heat Treatment

| Forging or hot rolling: | 1100 – 850°C |

| Normalising: | 840 – 880°C/air |

| Soft annealing: | 680 – 710°C/furnace |

| Hardening: | 820 – 860°C/water, oil |

| Tempering: | 550 – 660°C/air |

Hardening of DIN C45 Steel Hardening

Harden from a temperature of 820-860°C followed by water or oil quenching.

Heat to 820°C – 850°C hold until temperature is uniform throughout the section, soak for 10 – 15 minutes per 25mm of section, and quench in water or brine. Or,

Heat to 830°C – 860°C soak as above and quench in oil.Temper immediately while still hand warm.

Surface hardness for C45 special steel round bar after flame or induction hardning:

- Steel Name Steel number Surface Harndess

- C45 1.1191 min. 55 HRC

Application of DIN Carbon Steel C45 Round Bar

DIN C45 round bar steel material and steel plate C45, flats are widely used in all industry for uses which require more strength and wear resistance than the low carbon mild steel.

Quenched and subsequently tempered steel for C45 steel grade round bar, steel plate, flat and square is used for axles, bolts, forged connecting rods, crankshafts, torsion bars, light gears, guide rods, screws, forgings, wheel tyres, shafts, sickles, axes, knives, wood working drills, hammers, etc.