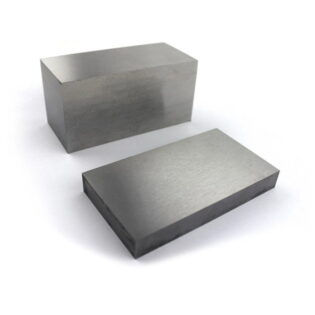

Cr12 Description

Cr12 is an alloy tool steel with good hardenability and good wear resistance. It is mainly used for cold stamping dies and punches, cold cutting scissors, drill sleeves, gauges, drawing dies, imprint dies, wire rubbing boards, drawing dies, thread rolling dies, etc.

China Grade: Cr12

China Standard: GB/T 1299-2000

Type: Alloy tool steels

Advantages: better hardenability and good wear resistance

Scope of application

It is a widely used cold work die steel with high strength, better hardenability and good wear resistance, but poor impact toughness. It is mainly used for cold stamping dies and punches, cold cutting scissors, drill sleeves, gauges, drawing dies, imprint dies, screw rubbing boards, drawing dies and thread rolling dies which bear small impact load and require high wear resistance.

Cr12 Introduction

Cr12 is a widely used cold work die steel with high strength, better hardenability and good wear resistance, but poor impact toughness. It is mainly used for cold stamping dies and punches, cold cutting scissors, drill sleeves, gauges, drawing dies, imprint dies, screw rubbing boards, drawing dies and thread rolling dies which bear small impact load and require high wear resistance.

Cr12 die steel belongs to high carbon and high chromium leistenite steel, which is also widely used in cold work die steel. The steel has good hardenability, wear resistance and thermal processability. Carbides are well distributed in steel and can be used to manufacture various cold working dies with complex shapes and heavy working conditions.

Such as cold die punch, thread rolling die, wire drawing die, material die, metallurgical powder die, woodworking cutting tools, cold cutting scissors drilling sleeve and gauges and other tools. In the process of research and development, after repeated exploration and test, we formulated a reasonable smelting technology and special ingot mold and forging technology, so that the material organization to achieve uniform, in addition to the standard material processing, bold innovation, the use of double knife chip new technology, greatly improve the efficiency, shorten the cycle, reduce the cost.

Features

1. The steel treated by vacuum degassing refining is pure.

2. Spheroidizing annealing and softening treatment, good cutting performance.

3. Enhanced element vanadium, molybdenum special addition, wear resistance is extremely excellent.

Use

1. Thin sheet not more than 2MM, high efficiency blanking die, punching die and stamping die.

2. All kinds of scissors, inserts, woodworking inserts.

3. Thread rolling mold and wear-resisting slide block.

4. Cold heading mold, thermosetting resin molding mold.

5. Stretch forming die, cold extrusion die.

State of supply

Annealed state, hardness 269-271HBW, indentation diameter 3. 7~4.1mm

Recommended products: Cr12MoV

Chemical Composition

Unit: (%)

C: 2.00 ~ 2.30

Si: 0.40 or less

Mn: 0.40 or less

S: 0.030 or less

P: 0.030 or less

Cr: 11.50 ~ 13.00

Ni: Allowable residual content ≤0.25

Cu: Allowable residual content ≤0.30

Co: 1.00 or less

Mechanical Properties

Hardness: annealing,269 ~ 271HB, indentation diameter 3.7 ~ 4.1mm;Quenching, acuity 58 HRC

Heat treatment

Metallographic structure: tempered martensite + undissolved carbide + residual austenite.

Delivery state: steel shall be delivered in annealed state.

Quenching Temperature

Cr12 quenched 950 ~ 1000°C oil quenching, secondary tempering 550°C

High temperature quenching 1100-1150°C, low temperature quenching 960-1050°C, tempering 550-650°C, the former has secondary hardening phenomenon, tempering not less than 2 times, 2h each time, after tempering can be air cooling or oil cooling, high temperature quenching before the best 2 times of preheating, at high temperature heating, need to take protective measures to prevent oxidation.

Tempering

| Application | Heating temperature/°C | Tempering time/h | Number of tempering | Hardness(HRC) |

| Eliminate stress and stabilize the structure Eliminate stress and reduce hardness | 180~200 320~350 | 2 2 | 1 1 | 60~62 57~58 |

Cr12 Quenching

Hardening heat/°C | Cooling medium | Hardness |

950~980 | Oil | 59~63 |

Treatment process

Cr12 section steel is widely used in mass production as a general cold working die, and its heat treatment methods usually have two kinds: primary hardening method (low quenching + low cycle) and secondary hardening method (high quenching + high cycle).

The quenching temperature of the primary hardening method is 1020 ~ 1040 degrees, and the tempering temperature can be selected according to the requirements of the die. Generally, the cold stamping die requiring high hardness and wear resistance is tempered at a low temperature of 160 ~ 180 degrees, and the hardness can reach HRC60 or more after tempering.

Requirements of higher hardness and a certain toughness of the stamping die, can be used 250~270 degrees of tempering, tempering hardness up to HRC58 ~ 60.For the high impact toughness of the die, can use 520 degrees of high temperature tempering, tempering hardness HRC55 ~ 57.

The quenching temperature of secondary hardness method is 1080 ~ 1120 degrees. Because there is a large amount of residual austenite in the quenched steel, so the hardness is low (HRC42 ~ 45). Through several times (3 ~ 5 times) high temperature tempering, the residual austenite is transformed into martensite, resulting in secondary hardening.

The hardness can rise to HRC59 ~ 64, which is mainly suitable for die parts requiring red hardness. The disadvantage is that the impact toughness is poor, which affects the multi-punching life, so it is not suitable for cold working die.

Because the primary hardening method adopts low temperature tempering, although the hardness can reach HRC60 or more, but the tempering temperature is low, the stress elimination after quenching is not sufficient, and in the subsequent processing, it is easy to reduce the surface hardness of the workpiece due to the grinding heat and affect the service life.

Therefore, medium temperature quenching + high temperature tempering method is preferred, that is, quenching at about 1050 degrees, and the hardness after quenching is HRC63.Then use 500 ~ 520 high temperature tempering.

Because the hardness after secondary hardening and tempering can reach HRC60 or more, the quenching temperature of this process is lower than that of the secondary hardening method, and the strength of the die after heat treatment is higher, and it has a certain toughness.Moreover, due to the full stress relief after high temperature tempering, it is not easy to crack in subsequent wire cutting discharge machining, is not easy to anneal in grinding, and the surface can be plated with titanium, which has been applied in production to some extent.

Cr12 Use

- The steel can be used for cold stamping dies of silicon steel, for deep drawing and punching dies with high wear resistance and simple shape under dynamic load conditions

- It is widely used to make cold working dies with complex shape, impact resistance and high wear resistance, such as silicon steel cold stamping dies, thread rolling dies and wire drawing dies.

- It is used to make concave touch requiring wear resistance in deep drawing die. The recommended hardness is 62~64HRC.

- for aluminum parts cold extrusion die punch, recommended hardness of 60~62HRC.

- It is used for making punch, die and insert which require high wear resistance and complex shape in bending die. The hardness of punch and die is recommended to be 60~64HRC.

- used to form the carbon mass fraction of 0.5%~0.80% of the steel plate, hardness of 37 ~42HRC, the service life can reach 220,000 times.

- It is used to make the bolt concave die for cold heading freight car. The part size is Ф 8.9mm × 9.0mm concentric cylinder, and the service life is only 0.1 thousand ~0.2 thousand times.

- For thermosetting plastic molding mold, high mushroom resistance, high strength mold is required.

- Compared with the original Q235 steel carbon mold, the service life of the wear-resistant brick forming die with boron + quenching + tempering can be increased by 5-6 times, the process is simple and the economic benefit is remarkable.

- After the solid boron and chromium of the Cr12 steel edge punch, the number of convex edge touching is up to 160,000 ~ 170,000 times. Conventional quenching process has only 60 thousand to 80 thousand times, and boron treatment has only 70 thousand to 10 thousand times.

- After vanadium composite treatment of CR12 steel rubbing wire plate, the service life of the die was extended to 17,000 pieces.

- The service life of the hexagonal die of cold heading hexagonal head bolt of CR12 steel has been increased by 10 times after vanadium composite treatment.