Introduction to SUM42 Free Cutting Steel:

SUM42 is a free cutting steel suitable for machining highly rigid parts such as lead screws, smooth rods, rack and spline shafts. Grade: SUM42 Application: It is suitable for machining parts requiring high rigidity Execution standard: JIS G4804-1999

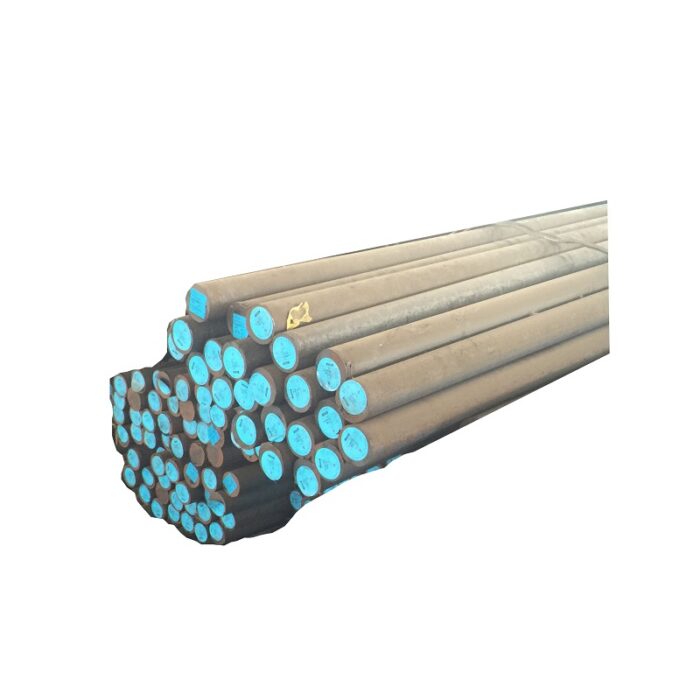

Category: Steel Round Bar

Tags: Cold Drawn Steel Bar Free cutting steel SUM42

SUM42 is a free cutting steel suitable for machining highly rigid parts such as lead screws, smooth rods, rack and spline shafts.

SUM42 Features

Executive standard :JIS G4804-1999, is high sulfur medium carbon free cutting steel, has better cutting performance, compared with 45 steel can increase the tool life four times, improve the production efficiency of 30%, has higher strength and hardness.

SUM42 Application

Suitable for machining parts requiring high rigidity, such as lead screw, smooth rod, rack and spline shaft, etc.

SUM42 Chemical Composition

C: 0.37~0.45 Si: 0.15~0.35 Mn: 1.20~1.55 S: 0.02~0.30 P: ≤0.05

SUM42 Mechanical Property

- Tensile strength σb (MPa) :(hot rolling)590 ~ 735; (high temperature tempering after cold drawing)590 ~ 785

- Elongation Δ5 (%) :(hot rolling)≥14; (cold rolled) 17 or more

- Section shrinkage ψ(%) :(hot rolling)≥20

- Hardness :(hot rolling)≤207HB; (cold drawn)179 ~ 229HB

- Status of delivery: hot rolled or cold drawn.

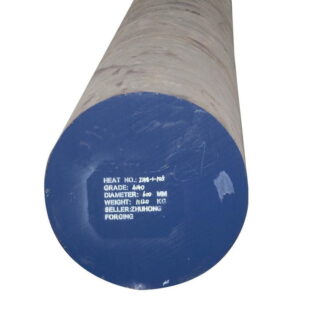

Can produce SUM42 specifications and size

- Round bar: Φ1 to Φ2000

- Square-shape steel/Flate bar: 10 to 1000

- Steel Plate/Sheet: 0.08 to 800(T)*10 to 1500(W)*Long

- Forging: Pipe/tube/slugs/donuts/cubes/other shapes

- Tubings: OD: Φ4-410; WT: 1-35 mm

- Steel coils and strip: THK:0.1mm Width:1500mmdiv

| Product type | Products | Dimension | Processes | Deliver Status |

|---|---|---|---|---|

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

Relate Steel Type:

12L14 Free Cutting Steel