42CrMo Alloy Steel

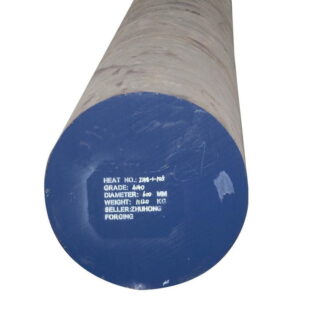

42CrMo steel belongs to alloy structural steel in terms of material classification. It has good mechanical properties and workability. It is widely used. There are mainly two types of materials, plate and round bar. Its comprehensive performance is better than 40cr, which has been recognized by the industry.

- Chinese name: 42 chromium molybdenum

- Foreign name: 42CrMo

- Alias: 42CrMo4

- Executive standard: National standard GB

- Origin: China

- Classification: Alloy structural steel

- Level: Premium product

- Specification: Plate , round bar

42CrMo Overview

42CrMo steel belongs to ultra-high-strength steel , with high strength and toughness, good hardenability, no obvious temper brittleness, high fatigue limit and multiple impact resistance after quenching and tempering, and good low-temperature impact toughness. 42CrMo steel is suitable for manufacturing large and medium-sized plastic molds that require certain strength and toughness .

42CrMo Chemical Composition

- Carbon C: 0.38~0.45%

- Silicon Si: 0.17~0.37%

- Manganese Mn: 0.50~0.80%

- Sulfur S: allowable residual content ≤0.035%

- Phosphorus P: allowable residual content ≤0.035%

- Chromium Cr: 0.90~1.20%

- Nickel Ni: allowable residual content ≤0.30%

- Copper Cu: allowable residual content ≤0.30%

- Molybdenum Mo: 0.15~0.25%

42CrMo Mechanical Properties

- Hardness: Annealed, 147~241HB, 42CrMo

- Mechanical properties of 42CrMo:

- Tensile strength σb (MPa): ≥1080(110)

- Yield strength σs (MPa): ≥930(95)

- Elongation δ5 (%): ≥12

- Reduction of area ψ (%): ≥45

- Impact energy Akv (J): ≥63

- Impact toughness value αkv (J/cm2): ≥78(8)

- Hardness: ≤217HB

In order to increase the mold life to more than 800,000 mold times, the hardening method of quenching and low temperature tempering can be implemented on the pre-hardened steel. When quenching, preheat at 500-600°C for 2-4 hours, and then keep it at 850-880°C for a certain period of time (at least 2 hours), then put it in oil and cool to 50-100°C and air cooling, the hardness can reach 50 after quench -52HRC, in order to prevent cracking, 200°C low temperature tempering treatment should be carried out immediately. After tempering, the hardness can be maintained above 48HRC.

Salt bath vanadium infiltration treatment

42CrMo Tempering

Program | Quenching temperature/°C | Temper | |||

Use | Heating temperature/°C | Medium | Hardness HRC | ||

(1) (2) (3) | 1020~1040 | Stress relief Remove stress and reduce hardness Remove stress and reduce hardness | 150~170 200~275 400~425 | Oil or nitrate — — | 61~63 57~59 55~57 |

(4) (5) (6) | 1115~1130 | Removal of stress and formation of secondary hardening Removal of stress and formation of secondary hardening Removal of stress and formation of secondary hardening | 510~520°C multiple tempering -78°C cold treatment Temper at 510~520°C once -78°C cold treatment plus 510~520°C tempering once, then -78°C cold treatment | — — — | 60~61 60~61 61~6 |

42CrMo Quenching

Program | First preheating/°C | Second preheating/°C | Quenching temperature/°C | cool down | Cool in the medium | Medium temperature/°C | medium | hardness (HRC) |

(1) (2) (3) (4) (5) | 550~660 | 840~860 | 950~1000 1020~1040 1020~1040 1115~1130 1115~1130 | oil oil Molten Nitrate oil Molten Nitrate | 20~60 20~60 400~550 20~60 400~450 | To room temperature To oil temperature 5~10min To oil temperature 5~10min | Air cooling Air cooling Air cooling Air cooling Air cooling | 58~62 62~63 62~63 42~50 42~50 |

Corresponding Grade

- Russia ГOCT 38XM,

- American AISI 4140/4142,

- British BS 708M40/708A42/709M40,

- French NF 40CD4/42CD4,

- German DIN 41CrMo4/42CrMo4,

- Japan JIS SCM4,

- International ISO 683/1 3

Quenching specification

General quenching and tempering specifications: quenching temperature 1000~1050°C, quenching oil or quenching gas, hardness ≥60HRC; tempering temperature 160~180°C, tempering time 2h, or tempering temperature 325~375°C, tempering times 2 ~3 times.

Physical properties

- Critical point temperature (approximate value): Ac1=730°C, Ac3=800°C, Ms=310°C.

- Linear expansion coefficient: temperature 20~100°C/20~200°C/20~300°C/20~400°C/20~500°C/20~600°C,

- Linear expansion coefficient: 11.1×10K/12.1×10K/12.9×10K/13.5×10K/13.9×10K14.1×10K.

- Elastic modulus: temperature 20°C/300°C/400°C/500°C/600°C,

- Elastic modulus 210000MPa/185000MPa/ 175000MPa/165000MPa/15500oMPa

Process Specification

Hot working specification

Hot working specificationTypical Application Examples