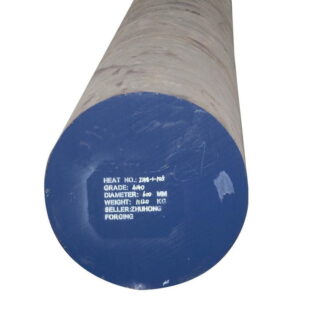

20CrNiMo Steel Round Bar

20CrNiMo, is a kind of alloy structural steel grade stipulated by the Chinese national standard. The 20CrNiMo round steel has high hardenability, no tempering brittleness, good weldability, little tendency to form cold crack, good machinability and cold strain plasticity. It is generally used under the condition of quenching and tempering or carburizing.

- Chinese Grade: 20CrNiMo

- Applicable fields: Iron and steel, industry

- Belongs to the discipline: Mechanics

- Meaning: Grade of alloy structural steel

- Uniform digital code: A50202

- Execution standard: GB/T3077-2018

Category: Steel Round Bar

Tag: 20CrNiMo

20CrNiMo Steel Round Bar

20CrNiMo steel originally is the steel number 8620 in AISI and SAE standards.The hardenability is similar to that of 20CrNi steel. Although the content of Ni in steel is half that of 20CrNi steel, the upper part of austenite isothermal transformation curve shifts to the right due to the addition of a small amount of Mo element.Moreover, due to the appropriate increase of Mn content, the hardenability of the steel is still good, and the strength is higher than that of 20CrNi steel.It is often used in the manufacture of small and medium-sized cars, tractors, engines and gears in transmission systems; Can also replace 12CrNi3 steel manufacturing requirements of higher core performance of carburizing parts, cyanide parts, such as oil drilling and metallurgical open pit roller bit tooth claw and cone body.20CrNiMo because of containing molybdenum in addition to good comprehensive properties but also a certain temperature resistance. Forgings for valve section of connecting rod for steam turbine gear, rotor and internal combustion engine.

20CrNiMo Chemical Component

Mass fraction (%) :

- C: 0.17 ~ 0.23

- Si: 0.17 ~ 0.37

- Mn: 0.60 ~ 0.95

- Sulfur S: ≤0.035

- P: ≤0.035

- Cr: 0.40 ~ 0.70

- Ni: 0.25 ~ 0.75

- Mo: 0.20 ~ 0.30

- Copper Cu: ≤0.30

20CrNiMo Mechanical Properties

Sample blank size: 15mm

Heat Treatment

- Quenching heating temperature (°C) : 850; Coolant: oil

- Tempering temperature (°C) : 200; Coolant: empty

- Tensile strength σb (MPa) : ≥980(100)

- Yield strength σs (MPa) : ≥785(80)

- Elongation Δ5 (%) : ≥9

- Section shrinkage ψ(%) : ≥40

- Impact work AKV (J) : ≥47

- Impact toughness value α kV (J/cm2) : ≥59(6) Brinell hardness (HBS100/3000) (annealing or high temperature tempering state) : ≤197

- Delivery status: delivery in heat-treated (normalizing, annealing or high temperature tempering) or unheat-treated condition, the delivery status shall be specified in the contract.

Density Calculation

- Square tube: (length + width) × thickness ×2×0.00785

- Cold plate: length × width × thickness ×0.00785

- Hot plate: length × width × thickness ×0.00785

- Welded pipe: (outer diameter – wall thickness) × wall thickness ×0.02466

- Flat steel: length × width ×0.00785

- Round steel: diameter × diameter ×0.00617

- Square steel: Length × Width ×0.00785

- Galvanized pipe :(outer diameter – wall thickness) × wall thickness ×0.02466×1.06

- Medium thick plate: length × width × thickness ×0.00785

- Galconized sheet: length × width × thickness ×0.00785×1.06

- Seamless tube :(outer diameter – wall thickness) × wall thickness ×0.02466

Expressive Methods

- The two digits at the beginning of the steel number represent the carbon content of the steel, which is expressed by a few thousandths of the average carbon content, such as 40Cr, 25Cr2MoVA alloy tube.

- The main alloying elements in the steel, except for some micro-alloying elements, are generally expressed by a few percent. When the average alloy content is less than 1.5%, only the elemental symbol is generally marked in the steel number, and not the content, but in special circumstances, easy to cause confusion, after the element symbol can also be marked with the number “1”, such as steel “12CrMoV” and “12Cr1MoV”, the former chromium content is 0.4-0.6%, the latter is 0.99-1.2%, All the other ingredients are the same. When the average content of alloying elements ≥1.5%, ≥2.5%, ≥3.5%…… , the content should be marked after the element symbol, which can be represented as 2, 3, 4…… And so on. For example, 18 cr2ni4wa.

- The alloying elements in steel, such as vanadium V, titanium Ti, aluminum Al, boron B and rare earth Re, are all micro-alloying elements. Although the content is very low, they should still be marked in the steel grade. For example, in 20MnVB steel. Vanadium is 0.07-0.12% and boron is 0.001-0.005%.

- The high quality steel should be added “A” at the end of the steel, in order to be different from the general high quality steel.

- Special purpose alloy structural steel, steel number with (or suffix) to represent the use of the symbol of the steel.

20CrNiMo Spot Specification

Name | Size/mm | Grade | Size/mm | Grade |

Bright round bar | 3.0-25 | 20CrNiMo | 4-10 | 20CrNiMo |

Hot rolled rounds | 12-50 | ⬆ | 8-10 | ⬆ |

Ф100-130 | ⬆ | 12-16 | ⬆ | |

Ф140-150 | ⬆ | 18-20 | ⬆ | |

Ф160-170 | ⬆ | 22-28 | ⬆ | |

Ф180-200 | ⬆ | 75-80 | ⬆ | |

Ф200-280 | ⬆ | 80-100 | ⬆ | |

500-1500 | ⬆ | 150 | ⬆ | |

Ф50-70 | ⬆ | 160 | ⬆ | |

Ф50-90 | ⬆ | 170 | ⬆ | |

Ф50-95 | ⬆ | 180 | ⬆ |

Application

Often used in the manufacture of small and medium-sized cars, tractors in the engine and gear transmission system, but also can replace 12CrNi3 steel manufacturing requirements of higher core performance of carburizing parts, cyanide parts, such as oil drilling and metallurgical open pit mine tooth claw and cone body.