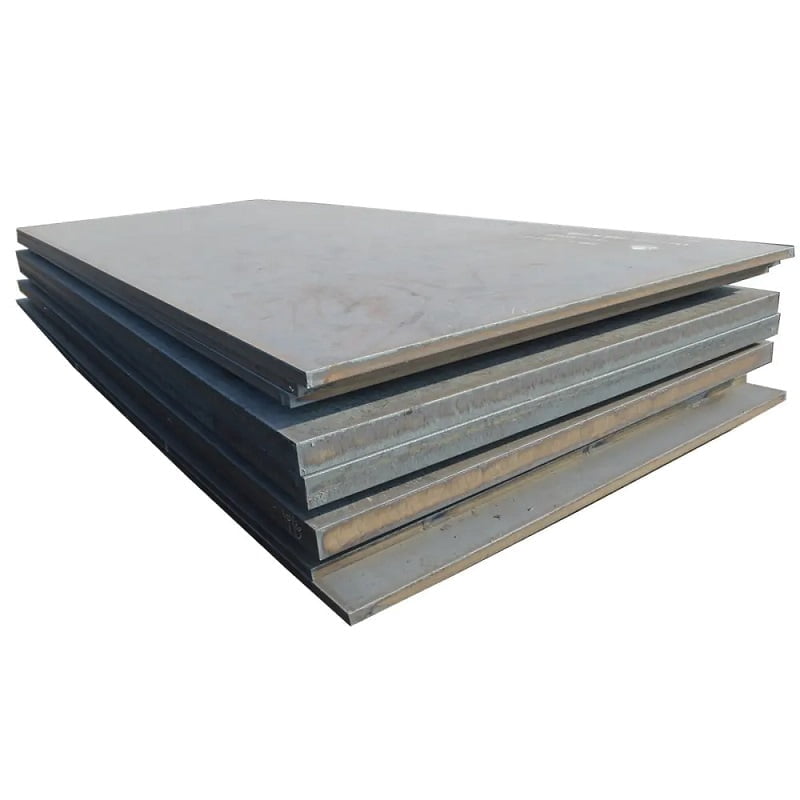

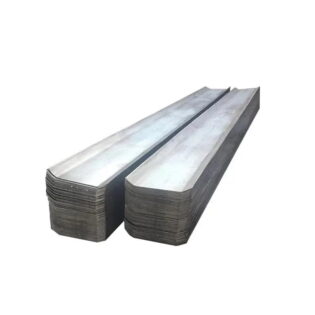

Q690D Steel Late Introduction

1, Q690D belongs to low alloy high strength structural steel plate, Q690D implementation standard for GB/T1591-2008 special technical conditions.

Q690D itself not only has this very high strength but also has a certain flexibility, wear resistance, fatigue resistance, impact resistance, easy processing and wear resistance, often used in the manufacturing industry for example; Mining machinery, crane, iron anchor, shield machine, hydraulic support, port machinery, Marine equipment bridge structure, etc

2, Q690D because it has enough high quality performance

First, it meets the needs of many manufacturing industries in material selection

Second, the high quality performance in the process of use has also been deeply loved and praised by the manufacturing industry. Later, because of the recognition of the society, the frequent use of the manufacturing industry and the continuous optimization of the manufacturer, Q690D has gradually become one of the commonly used raw materials in the manufacturing industry.

Steel plates made from Q690 material has high yield strength and tensile strength and is widely used in coal mine machinery and engineering machinery, such as hydraulic support, port cranes, flatbed trucks and so on.

Q690 Steel Chemical Composition

The chemical compositon of <CLASS C D E> are displayed in the following table.

| ||||||||||||||||

| Steel Grade | Quality Grade | C | Si | Mn | P | S | Nb | V | Ti | Cr | Ni | Cu | N | Mo | B | Al |

| Q690 | C | ≤ 0.18 | ≤ 0.60 | ≤ 2.00 | ≤0.030 | ≤0.030 | ≤ 0.11 | ≤ 0.12 | ≤ 0.20 | ≤ 1.00 | ≤ 0.80 | ≤ 0.80 | ≤ 0.015 | ≤ 0.30 | ≤ 0.004 | ≥ 0.015 |

| D | ≤0.030 | ≤0.025 | ||||||||||||||

| E | ≤0.025 | ≤0.020 | ||||||||||||||

Carbon Equivalent Value (CEV): ≤0.49% (including C, D, E; all diameter)

Q690 Steel Mechanical Properties

| Q690 Yield Strength (≥N/mm2); Thickness or Dia. d (mm) | ||||||

| Standard | Steel Grade | Quality | d≤16 | 16<d≤40 | 40<d≤63 | 63<d≤80 |

| GB/T 1591 – 2008 | Q690 | C, D, E | 690 | 670 | 660 | 640 |

| GB/T 1591 – 2018 | Q690M | C, D, E | 690 | 680 | 670 | 650 |

| Q690 Tensile Strength (N/mm2); d (mm) | Elongation | |||||

| Standard | Steel Grade | Quality | d≤40 | 40<d≤63 | 63<d≤80 | % |

| GB/T 1591 – 2008 | Q690 | C, D, E | 770-940 | 750-920 | 730-900 | ≥14 |

| GB/T 1591 – 2018 | Q690M | C, D, E | 770-940 | 750-920 | 730-900 | ≥14 |

1 Mpa= 1N/mm2

Q690M: “M” means TMCP (Thermal Mechanical Control Processing)

Welding crack sensitivity index (Pcm): ≤0.25% (Only for bars)

Charpy Impact Test of Q690 Material

| Charpy Impact Test (V) – Test temperature and impact absorbed energy | ||||

| Grade | Quality Class | Test Temp. (℃) | Thickness | Absorbed Energy (KV2/J) |

| Q690 steel | C | 0 | 12mm-150mm | ≥55 |

| D | -20 | ≥47 | ||

| E | -40 | ≥31 | ||

| Impact test to take longitudinal samples. | ||||