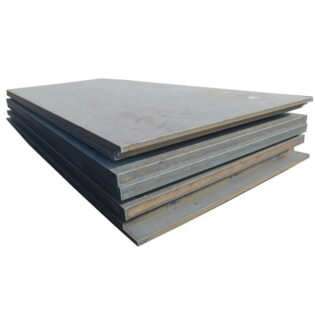

Q355 Steel Description

Q355 is a kind of steel. It is a kind of low alloy high strength structural steel, widely used in Bridges, vehicles, ships, construction, pressure vessels, special equipment, etc., where “Q” means yield strength, 355 means the yield strength of this steel is 355MPa, and the yield value will decrease with the increase of the thickness of the material.

Chemical composition:

C: 0.24, Si: 0.55, Mn: 1.60, P: S: 0.035, 0.035, Cr: 0.30, Ni: 0.30, Cu: 0.40

Datasheet and Specification

The tables below shows the Q355 material datasheet and specifications such as chemical composition, and mechanical properties.

Q355 Steel Chemical Composition (Hot rolled)

| Steel Grade | Quality Grade | C % (≤) | Si % (≤) | Mn (≤) | P (≤) | S (≤) | Cr (≤) | Ni (≤) | Cu (≤) | N (≤) |

| Q355 | Q355B | 0.24 | 0.55 | 1.6 | 0.035 | 0.035 | 0.30 | 0.30 | 0.40 | 0.012 |

| Q355C | 0.20 | 0.030 | 0.030 | 0.012 | ||||||

| Q355D | 0.20 | 0.025 | 0.025 | – |

Carbon Equivalent (CEV)

Based on smelting analysis, steel delivered in hot rolled state.

| CEV (Mass fraction ≤%); Nominal thickness or diameter (d) | ||||||

| Steel Grade | Quality Grade | ≤ 30 | 30 < d ≤ 63 | 63 < d ≤ 150 | 150 < d ≤ 250 | 250 < d ≤ 400 |

| Q355 | Q355B | 0.45 (CEV) | 0.47 | 0.47 | 0.49 | – |

| Q355C | – | |||||

| Q355D | 0.49 | |||||

Q355 Mechanical Properties (Hot rolled)

Notes:

- 1 MPa = 1 N/mm2

- 1 GPa = 1 kN/mm2

| Yield Strength (≥N/mm2), Thickness or Dia. (d) in mm | ||||||||||

| Steel Grade | Quality Level | d≤16 | 16< d ≤40 | 40 < d ≤63 | 63 < d ≤ 80 | 80< d ≤ 100 | 100< d≤ 150 | 150 < d≤ 200 | 200 < d ≤ 250 | 250 < d ≤ 400 |

| Q355 | Q355B | 355 | 345 | 335 | 325 | 315 | 295 | 285 | 275 | – |

| Q355C | – | |||||||||

| Q355D | 265 | |||||||||

| Tensile Strength (N/mm2), Dia. (d) mm | |||||

| Steel Grade | Quality Level | d≤100 | 100 < d ≤ 150 | 150 < d ≤ 250 | 250 < d ≤ 400 |

| Q355B,C,D | Q355B | 470 – 630 | 450 – 600 | 450 – 600 | – |

| Q355C | – | ||||

| Q355D | 450 – 600 | ||||

Q355 Steel Elongation

| Dia. (d) mm; Elongation (%) | ||||||

| Sample direction | d≤40 | 40 < d ≤ 63 | 63 < d ≤ 100 | 100 < d ≤ 150 | 150 < d≤ 200 | 250 < d ≤ 400 |

| Horizontal | 20 | 19 | 18 | 18 | 17 | 17 |

| Vertical | 22 | 21 | 20 | 18 | 17 | 17 |

Charpy Impact

Charpy (V-notch) impact test temperature and impact absorption energy (KV2/J).

| Quality | Temperature | Longitudinal Impact Energy (J), ≥ | Transverse Impact Energy (J), ≥ |

| Q355B | 20 ℃ | 34 | 27 |

| Q355C | 0 ℃ | 34 | 27 |

| Q355D | -20 ℃ | 34 (for thickness ≥250mm) | 27 (for thickness ≥250mm) |

Features and Applications

Q355 steel has good mechanical properties, good weldability, hot and cold processing properties and corrosion resistance. Can be used to manufacture ships, boilers, pressure vessels, petroleum storage tanks, bridges, power station equipment, lifting transport machinery and other higher load welded structural parts.

Q355 Steel Equivalent Grade

Q355 carbon steel equivalent to European EN (German DIN EN, British BSI, French NF…) and ISO standard.

| China | ISO | European Union | |||

| Standard | Grade | Standard | Grade | Standard | Grade (Material Number) |

| GB/T 1591 -2018 | Q355B | ISO 630-2 | S355B | EN 10025-2 | S355, S355JR (1.0045) |

| Q355C | S355C | S355J0 (1.0553) | |||

| Q355D | S355D | S355J2 (1.0577) | |||