Description

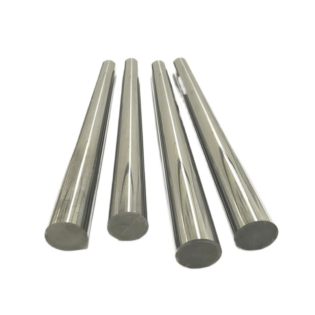

We can supply all kinds of bars, forgings, rings, hot rolled plates, cold rolled plates, strips, pipes and wires.

Sheet and strip are generally supplied after hot or cold rolling, annealing or solution, pickling and polishing.

Bars, forgings and rings can be supplied in forged or hot rolled state; Can also be supplied after forging solution treatment; The bar can be supplied after solution polishing or carding, and can be placed in cold drawing condition when required by order.

Silk material can be supplied in solution state; For the wire with nominal diameter or thickness below 6.35mm, it can be supplied by 50% ~ 65% cold drawing deformation after solid solution; Wire with nominal diameter or side length greater than 6.35mm shall be supplied with no less than 30% cold drawing deformation after solution treatment. For wire with nominal diameter or side length not more than 0.65mm, it shall be supplied with no less than 15% cold drawing deformation after solution treatment according to requirements.

Inconel X-750 Chemical composition:

Alloy | % | Ni | Cr | Fe | Nb | Co | C | Mn | Si | S | Cu | Al | Ti |

Inconel X-750 | Min. | 14 | 5.0 | 0.7 | 0.4 | 2.25 | |||||||

Max. | 70 | 17 | 9.0 | 1.2 | 1.00 | 0.08 | 1.00 | 0.5 | 0.01 | 0.5 | 1.0 | 2.75 |

Inconel X-750 Physical properties:

Density | 8.28 g/cm3 |

Melting range | 1393-1427℃ |

Inconel X-750 Alloy minimum Mechanical properties in the room temperature:

Alloy | Tensile strength | Yield strength | Elongation | Brinell hardness HB |

Solution treatment | 1267 | 868 | 25 | ≤400 |

Machinability:

Corrosion resistance:

Inconel X-750 has excellent resistance to chloride ion stress-corrosion cracking. It exhibits satisfactory resistance to numerous oxidizing environments. The alloy has similar corrosion resistance to alloy 600 in many media.

Application range and field:

- Nuclear reactors

- Gas turbines

- Rocket engines

- Pressure vessels

- Aircraft structures