Duplex 2205 Stainless Steel Introduction

The yield strength of 2205 duplex stainless steel is more than twice that of ordinary austenitic stainless steel .This feature enables designers to reduce weight when designing products, making this alloy more cost-effective than 316 and 317L.2205 alloy is particularly suitable for the temperature range of -50°F/+600°F. For applications beyond this temperature range, this alloy can also be considered, but there are some limitations, especially when applied to welded structures.Application Structure Processing Chemical composition Mechanical Properties Advantage Disadvantage

Duplex 2205 Application

- Pressure vessels, high-pressure storage tanks, high-pressure pipes, heat exchangers (chemical processing industry).

- Oil and gas pipelines, heat exchanger fittings.

- Sewage treatment system.

- Pulp and paper industry classifiers, bleaching equipment, storage and processing systems.

- Rotary shafts, press rolls, blades, impellers, etc. under high-strength and corrosion-resistant environments.

- Cargo boxes of ships or trucks

- Food processing equipment

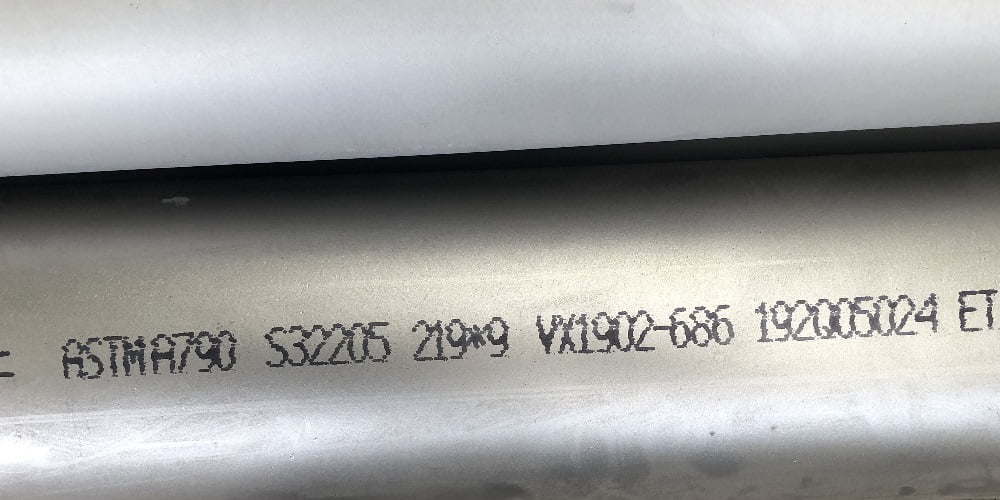

Standard

- ASTM/ASME………..A240 UNS S32205/S31803

- EURONORM………..1.4462 X2CrNiMoN 22.5.3

- AFNOR……………….Z3 CrNi 22.05 AZ

- DIN…………………….W. Nr 1.4462

Corrosion resistance

Uniform corrosion

Due to the chromium content (22%), molybdenum (3%) and nitrogen content (0.18%), the corrosion resistance of 2205 is better than 316L and 317L in most environments.

Local corrosion resistance

The content of chromium, molybdenum and nitrogen in 2205 duplex stainless steel makes it highly resistant to pitting and crevice corrosion in oxidizing and acidic solutions.

Stress corrosion resistance

The dual-phase microstructure of stainless steel helps to improve the stress corrosion cracking resistance of stainless steel. In the presence of certain temperature, strain, oxygen and chloride, austenitic stainless steel will undergo chloride stress corrosion. Because these conditions are not easy to control, the use of 304L, 316L and 317L is restricted in this regard.

Anti-corrosion fatigue

The high strength and corrosion resistance of 2205 duplex steel make it have high corrosion fatigue strength. Processing equipment is susceptible to corrosive environments and loading cycles, and the characteristics of the 2205 are very suitable for such applications.

Duplex 2205 Structure

The chemical composition of 2205 can obtain the ideal microstructure 50 α / 50 γ after 1900°/1922°F (1040°/1080°C) solution annealing treatment. If the heat treatment temperature is higher than 2000°F, it may cause an increase in the ferrite composition.Like other duplex stainless steels , 2205 alloy is susceptible to the precipitation of intermetallic phases. The intermetallic phase precipitates between 1300°F and 1800°F, and the precipitation rate is the fastest at 1600°F. Therefore, we need to test 2205 to ensure that there is no intermetallic phase. The test refers to ASTM A 923.

Thermoforming

We recommend that the forming should be done at temperatures below 600°F as much as possible. During the hot forming process, the entire workpiece should be heated as a whole, and should be carried out in the temperature range of 1750°F to 2250°F.Alloy 2205 is very soft at this temperature. If the temperature is too high, 2205 alloy is prone to hot tearing. If it is lower than this temperature, austenite will fracture. Below 1700°F, the intermetallic phase will form quickly due to the influence of temperature and deformation.After the hot forming is completed, it should be solid-solution annealed at a minimum temperature of 1900°F and quenched to restore its phase balance, toughness and corrosion resistance.We do not recommend stress relief, but if you must do so, the material should be solid solution annealed at a minimum temperature of 1900°F, then quickly cooled and water quenched.

Cold forming

2205 alloy can be cut and cold formed. However, due to the high strength and hardness of 2205 alloy itself, it needs more cold forming than austenitic steel. It is also because of its high strength that the springback must be fully considered.

Heat treatment

Alloy 2205 should be annealed at a minimum temperature of 1900°F, then rapidly cooled and water quenched. This treatment is used for solution annealing and stress relief.If the stress relief treatment is performed at a temperature lower than 1900°F, it is easy to cause the precipitation of harmful metallic or non-metallic phases.

Machinability

On high-speed machine tools, the feed rate and cutting speed of 2205 alloy are the same as those of 316L. If a carbonized knife is used, the cutting speed is reduced by about 20% compared with 316L. The performance of the machine and its components plays a key role here.

Welding

The weldability of 2205 alloy is very good. The required performance of 2205 alloy is that the weld metal and thermally deteriorated parts still maintain the same corrosion resistance, strength and toughness as the base metal.The welding of 2205 is not difficult, but the welding procedure needs to be designed so that after welding, it can maintain a good phase balance and avoid the precipitation of harmful metal phases or non-metal phases.2205 can be welded in the following equipment: GTAW (TIG); GMAW (MIG); SMAW (“stick” electrode); SAW; FCW; and PAW

Features:

1. 2205 duplex stainless steel alloy as compared with austenitic stainless steel 316L and 317L, 2205 superior performance in resistance to pitting and crevice corrosion aspect, it has a high corrosion resistance, as compared with austenite, it The coefficient of thermal expansion is lower and the thermal conductivity is higher.

2. Compared with austenitic stainless steel, duplex stainless steel 2205 alloy has twice its compressive strength. Compared with 316L and 317L, the designer can reduce its weight. Alloy 2205 is especially suitable for the temperature range of -50°F/+600°F. Under strict restrictions (especially for welded structures), it can also be used at lower temperatures.

Duplex 2205 Chemical Composition

Performance supplement: main component: 22Cr-5.3Ni-3.2Mo-0.16N; national standards: NAS 329J3L, UNS S32205/S31803, DIN/EN 1.4462, ASTM A240, ASME SA-240; mechanical properties: tensile strength: σb≥ 640Mpa; Elongation: δ≥25%; Typical working conditions: 20% dilute sulfuric acid, below 60℃, annual corrosion rate <0.1mm; Matching welding wire: ER2209.1. Chemical composition (JIS G 4305-005) (wt%)

| Chemical composition | C | Si | Mn | P | S | Cr | Ni | Mo | N |

| Standard | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.04 | ≤0.03 | 21.0~24.0 | 4.5~6.5 | 2.5~3.5 | 0.08~0.2 |

| General | 0.025 | 0.6 | 1.5 | 0.026 | 0.001 | 22.5 | 5.8 | 3.0 | 0.16 |

2. Performance (JIS G 4305-2005)

| Distinguish | Mechanical properties | Remarks | | |

| Ys (Mpa) | Ts (Mpa) | El (%) | Hv | 2.0t/2B |

| ≥450 | ≥620 | ≥25% | ≥18 | ≤ 320 |

| 500 | 670 | 35% | 27 | 280 |

3. Physical properties

| Density(g/cm) | Magnetic | Specific heat(J/gC) | Thermal conductivity100C(W/m. | Thermal expansion rate20~100C(10/C) |

| 7.8 | Have | 0.45 | 19.0 | 13.7 |

Duplex 2205 Mechanical Properties

| Room temperature mechanical properties of 2205 duplex stainless steel |

| Steel grade | Product specifications | tensile strength | Yield Strength | Elongation | |

| MPa | MPa | % | |

| 00Cr22Ni5Mo3N | Φ20mm, bar | ≥680 | ≥450 | ≥25 | |

| SAF 2205 | Wall thickness ≤20mm, pipe | 680/880 | >450 | >25 | |

| Blank thickness ≤200mm, forging | 680/880 | >410 | >25 [1] | |

High temperature mechanical properties of 2205 duplex stainless steel

|

| Steel grade | Product specifications | tensile strength | Yield Strength | Elongation | temperature |

| MPa | MPa | % | °C |

| 00Cr22Ni5Mo3NSAF 2205 | Φ20mm, bar | 710 | 470 | 37 | 100 |

| 680 | 393 | 32 | 200 |

| 650 | 380 | 30 | 300 |

| | | | |

| Wall thickness ≤20mm, pipe | >630 | >370 | | 100 |

| >580 | >330 | | 200 |

| >560 | >310 | | 300 |

| | | | |

| Blank thickness ≤200mm, forging | >630 | >365 | | 100 |

| >580 | >315 | | 200 |

| >560 | >285 | | 300 |

Duplex 2205 Steel Advantage

- 2205 stainless steel plate, 2205 stainless steel, duplex stainless steel 2205, 2205 stainless steel materials, are Swedish stainless steel grades.

The difference between duplex 2205 stainless steel plate and austenitic 304 stainless steel plate

- The yield strength is more than twice that of ordinary austenitic stainless steel, and it has the necessary requirements for forming

Sufficient plasticity. The wall thickness of storage tanks or pressure vessels made of duplex stainless steel is 30-50% less than that of commonly used austenite, which is beneficial to reduce costs.

- It has excellent resistance to stress corrosion cracking. Even the duplex stainless steel with the lowest alloy content has higher resistance to stress corrosion cracking than austenitic stainless steel, especially in an environment containing chloride ions. Stress corrosion is a prominent problem that is difficult to solve for ordinary austenitic stainless steel.

- The corrosion resistance of 2205 duplex stainless steel, which is most commonly used in many media, is better than that of ordinary 316L austenitic stainless steel, while super duplex stainless steel has extremely high corrosion resistance. In some media, such as acetic acid and formic acid It can even replace high-alloy austenitic stainless steel and even corrosion-resistant alloys .

- It has good local corrosion resistance. Compared with austenitic stainless steel with the same alloy content, its wear corrosion resistance and fatigue corrosion resistance are better than austenitic stainless steel.

- The coefficient of linear expansion is lower than that of austenitic stainless steel , which is close to that of carbon steel. It is suitable for connection with carbon steel and has important engineering significance, such as the production of composite plates or linings.

- Whether under dynamic or static load conditions, it has a higher energy absorption capacity than austenitic stainless steel. This is for structural parts to cope with sudden accidents such as collisions and explosions. Duplex stainless steel has obvious advantages and has practical application value.

Duplex 2205 Stainless Steel Disadvantage

Compared with austenitic stainless steel, the disadvantages of duplex stainless steel are as follows:

- The universality and versatility of application are not as good as austenitic stainless steel. For example, its service temperature must be controlled below 250 degrees Celsius.

- Its plastic toughness is lower than that of austenitic stainless steel, and its cold and hot processing technology and forming performance are not as good as austenitic stainless steel.

- There is a medium temperature brittle zone, and the process system of heat treatment and welding needs to be strictly controlled to avoid the appearance of harmful phases and damage performance.

The difference between duplex 2205 stainless steel plate and ferritic 410 stainless steel plate:Comprehensive mechanical properties are better than ferritic stainless steel , especially plastic toughness, not as sensitive to brittleness as ferritic stainless steel.

- Except for stress corrosion resistance, other local corrosion resistance is better than ferritic stainless steel.

- Cold working process performance and cold forming performance are far better than ferritic stainless steel.

- The welding performance is also much better than that of ferritic stainless steel. Generally, there is no need for preheating before welding and no heat treatment after welding.

- The application range is wider than ferritic stainless steel. Compared with ferritic stainless steel, the disadvantages of duplex stainless steel are as follows: The content of alloying elements is high and the price is relatively high. Generally, ferrite does not contain nickel.

The yield strength of 2205 duplex stainless steel is more than twice that of ordinary austenitic stainless steel .This feature enables designers to reduce weight when designing products, making this alloy more cost-effective than 316 and 317L.2205 alloy is particularly suitable for the temperature range of -50°F/+600°F. For applications beyond this temperature range, this alloy can also be considered, but there are some limitations, especially when applied to welded structures.Application Structure Processing Chemical composition Mechanical Properties Advantage Disadvantage

The yield strength of 2205 duplex stainless steel is more than twice that of ordinary austenitic stainless steel .This feature enables designers to reduce weight when designing products, making this alloy more cost-effective than 316 and 317L.2205 alloy is particularly suitable for the temperature range of -50°F/+600°F. For applications beyond this temperature range, this alloy can also be considered, but there are some limitations, especially when applied to welded structures.Application Structure Processing Chemical composition Mechanical Properties Advantage Disadvantage