Product Detail

Place of Origin: China

Brand Name: LION

Certification: ISO9001:2005

Grade: Alloy 718

Minimum Order Quantity: 30kg

Price: According to your purchase quantity and size

Packaging Details: wooden box

Delivery Time: 15-20 days

Payment Terms: T/T L/C

Supply Ability: 200000KG/MONTH

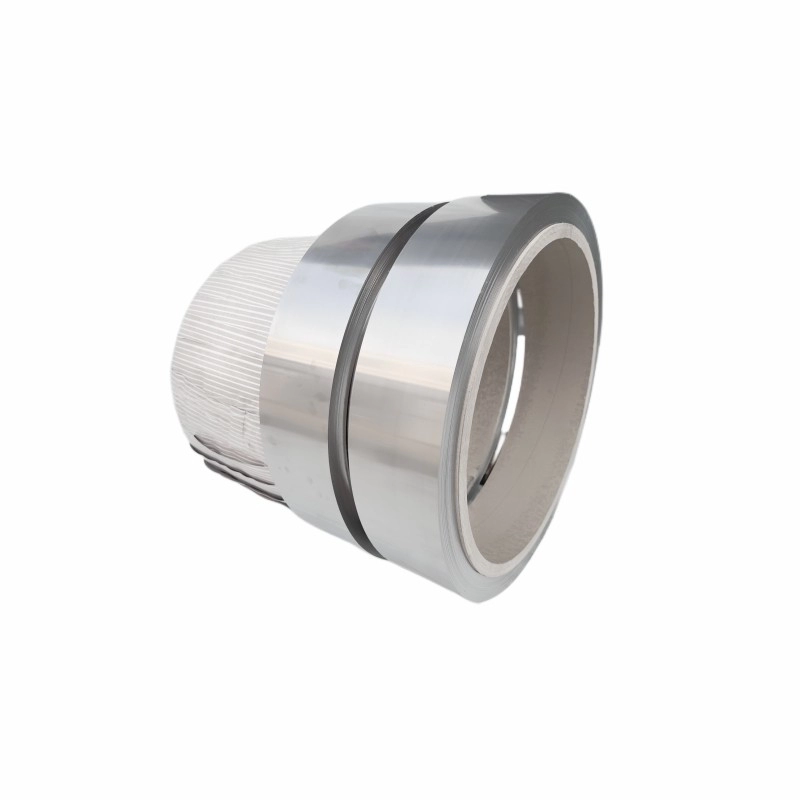

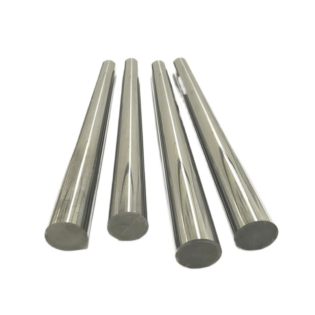

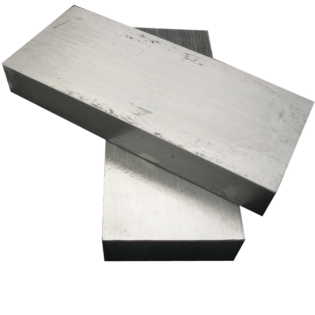

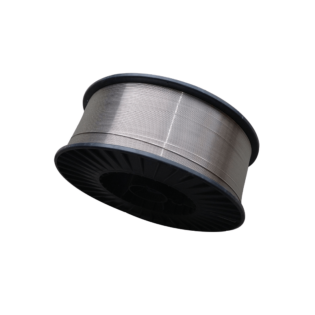

Features: | Fatigue Resistance, Radiation Resistance, Oxidation Resistance, Corrosion Resistance | Shape: | Wire,Strip,Rod,Pipe,Plate |

Delivery State: | Sosoloid | Application: | Parts For Aero-engine, Nuclear Energy Industry And Petroleum Applications |

Size: | Negotiable | Executive Standard: | ASTM |

Raw Materials: | NI50-55%, CR17-21%, NB4.75-5.5%, MO2.8-3.3% | Alloy Type: | Nickel-based Deformed Superalloy |

Product Description: Inconel Alloy is a nickel-chromium-molybdenum-niobium alloy with a high resistance to corrosion and oxidation, as well as fatigue and radiation resistance. It is also known as UNS N06625 or Inconel 625 and is identified by the material number 2.4856. Commonly used in various industries, Inconel Alloy contains the following materials: Nickel (Ni) 50-55%, Chromium (Cr) 17-21%, Niobium (Nb) 4.75-5.5%, and Molybdenum (Mo) 2.8-3.3%.

Inconel Alloy is available in numerous shapes, such as wire, strip, rod, pipe, and plate, and is made according to the ASTM standard. The material is characterised by its exceptional fatigue resistance and excellent oxidation and corrosion resistance, making it suitable for high-temperature applications. Inconel 625 is delivered in a solid state and has a wide range of applications, including aerospace engineering, chemical processing, nuclear engineering, and marine engineering.

Features:

- Product Name: Inconel Alloy

- Shape: Wire, Strip, Rod, Pipe, Plate

- Raw Materials: NI50-55%, CR17-21%, NB4.75-5.5%, MO2.8-3.3%

- Features: Fatigue Resistance, Radiation Resistance, Oxidation Resistance, Corrosion Resistance

- Alloy Type: Nickel-based Deformed Superalloy

- Application: Parts For Aero-engine, Nuclear Energy Industry And Petroleum Applications

- No 6625, UNS N06625, Inconel 625 seamless pipe

Applications:

Customization:

LION’s Inconel Alloy has an excellent performance of Nickel-based Deformed Superalloy, its executive standard is ASTM. It is widely used in nickel-based alloy, such as Inconel 625 Capillary and Inconel 625, NC22DNb, Inconel 718 etc. It has a variety of shapes, such as Wire, Strip, Rod, Pipe, Plate, etc., and its delivery state is sosoloid.

We provide customized service for Inconel Alloy. The Brand Name is LION, Model Number is inconel 718, Place of Origin is China, Certification is ISO9001:2005, Minimum Order Quantity is 30kg, Price is 50-52 USD/kg, Packaging Details is wooden box, Delivery Time is 15-20 days, Payment Terms is T/T L/C, Supply Ability is 100000KG/MONTH and Size is Negotiable.

Process performance and requirements

Thermal processing

The suitable thermal processing temperature is 1120-900℃. The cooling water can be extinguished or other forms. Rapid thermal annealing should be followed by cooling in time to ensure good performance. Thermal processing materials should be heated to a temperature limit to ensure that the final processing temperature of the processed plastic when the deformation reaches 20% should not be lower than 960°C.

Cold working

Solution treatment should be carried out after cold working. The work hardening rate is greater than that of austenitic stainless steel, so the processing equipment should be adjusted accordingly, and there should be an intermediate annealing process during the cold working process.

Welding process

The alloy has satisfactory welding performance and can be welded by argon arc welding, electron beam welding, seam welding, spot welding and other methods.

Parts heat treatment process

The heat treatment of aviation parts is usually carried out according to the standard heat treatment system and the direct aging heat treatment system.

Application scope

Due to its high temperature strength, excellent corrosion resistance and easy processability at 700°C, 718 can be widely used in various high-demand situations.

Support and Services:

Inconel Alloy is a nickel-chromium-based alloy, designed to provide superior corrosion and oxidation resistance for a wide variety of applications. Our technical support team is dedicated to providing customers with fast and knowledgeable service. Our team is available to answer any questions about ordering, installation, setup, maintenance, troubleshooting and repair.

Our services include:

- Help selecting the right Inconel Alloy product for your application

- Provide installation and maintenance instructions

- Answer technical questions

- Provide troubleshooting and repair assistance

- Provide product information and updates

- Provide customer support and satisfaction

If you have any questions or require technical support, please contact us at any time.

FAQ:

Q1: What is Inconel Alloy?

A1: Inconel Alloy is a nickel-chromium-molybdenum alloy with good corrosion resistance and high temperature strength. It is manufactured by LION and its model number is inconel 718.

Q2: Where is Inconel Alloy made?

A2: Inconel Alloy is made in China and has the ISO9001:2005 certification.

Q3: What is the minimum order quantity for Inconel Alloy?

A3: The minimum order quantity for Inconel Alloy is 30kg.

Q4: How much does Inconel Alloy cost?

A4: The price of Inconel Alloy is 50-52 USD/kg.

Q5: What is the delivery time for Inconel Alloy?

A5: The delivery time for Inconel Alloy is 15-20 days.