6061 Aluminum Alloy Product Introduction

Chemical Composition

| Element | Composition (%) |

|---|

| Silicon (Si) | 0.40 – 0.8 |

| Iron (Fe) | 0.70 max |

| Copper (Cu) | 0.15 – 0.40 |

| Manganese (Mn) | 0.15 max |

| Magnesium (Mg) | 0.80 – 1.20 |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | 0.25 max |

| Titanium (Ti) | 0.15 max |

| Others | 0.05 max each, 0.15 max total |

Mechanical Properties

| Property | Value |

|---|

| Tensile Strength (MPa) | 310 |

| Yield Strength (MPa) | 276 |

| Elongation at Break (%) | 12 |

| Hardness (Brinell) | 95 HB |

Performance at Different Temperatures

- Good performance at room temperature with stable mechanical properties.

- Maintains strength and toughness at low temperatures.

- Slightly decreases in strength at higher temperatures above 100°C.

Industrial Applications

| Industry Sector | Applications |

|---|

| Aerospace | Aircraft structures, fuselage panels |

| Automotive | Vehicle frames, wheels, automotive parts |

| Marine | Boat hulls, components exposed to saltwater |

| Construction | Structural components, bridges, scaffolding |

| Consumer Goods | Bicycle frames, sporting equipment |

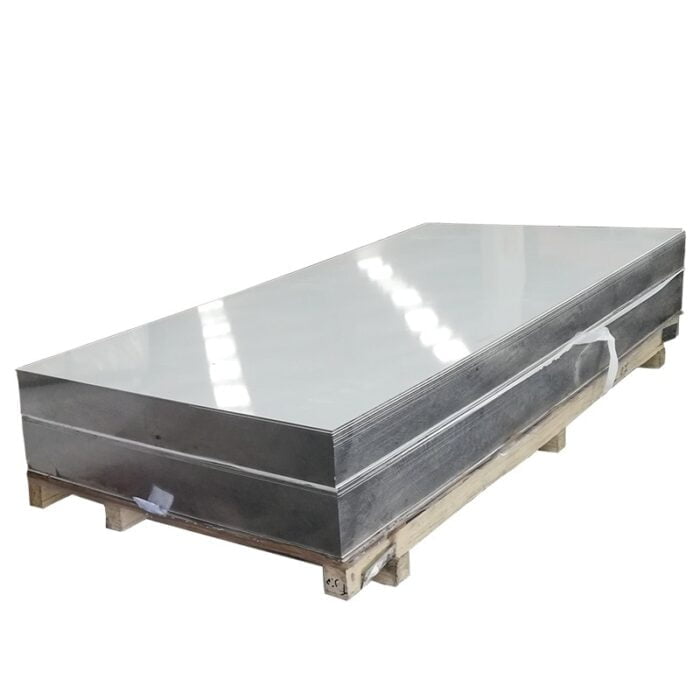

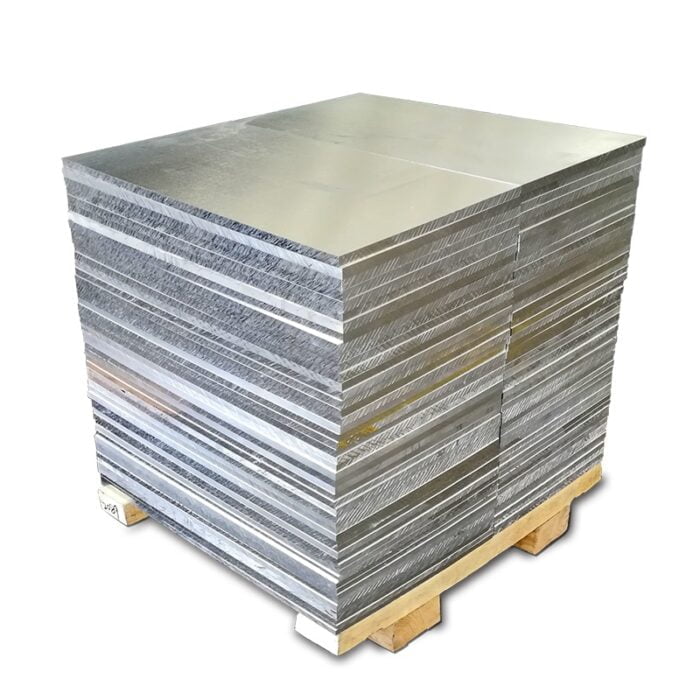

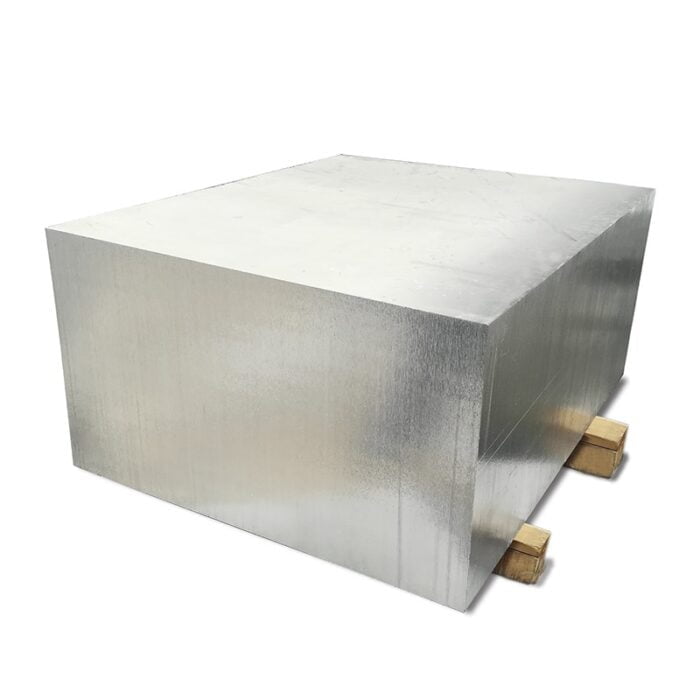

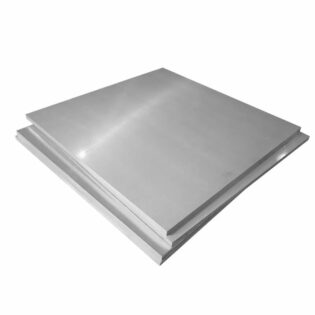

Shapes and Sizes

- Forms: Sheets, plates, bars, tubes, extrusions.

- Sizes: Thickness ranging from 0.2 mm to 200 mm, various shapes and dimensions available.

Production Standards

- ASTM B209: Standard specification for aluminum and aluminum-alloy sheet and plate.

- Various international standards based on application and manufacturing requirements.

Standards and Corresponding Grades

| Country/Region | Standards | Corresponding Grades |

|---|

| USA | ASTM B209 | 6061 |

| Europe | EN 573, EN 485 | EN AW-6061 |

| Japan | JIS H4000, JIS H4040 | JIS A6061 |

| China | GB/T 3190, GB/T 3880 | 6061A |

Welding and Processing

| Welding Methods | Processing Methods |

|---|

| TIG, MIG, Resistance | Cutting, drilling, machining |

Heat Treatment and Cold Processing

- Responds well to heat treatment for improving strength and hardness.

- Cold working can enhance mechanical properties but may reduce formability.

Advantages and Disadvantages

| Advantages | Disadvantages |

|---|

| High strength-to-weight ratio | Lower corrosion resistance than some alloys |

| Good machinability | More expensive than some aluminum alloys |

| Versatile applications across industries | Limited to moderate formability in certain processes |

Similar Products and Comparison

| Alloy Type/Property | 6061 Alloy | 6063 Alloy | 7075 Alloy |

|---|

| Composition (%) | Si: 0.40-0.8 | Si: 0.20-0.6 | Si: 0.40 |

| Tensile Strength (MPa) | 310 | 185 | 570 |

| Yield Strength (MPa) | 276 | 145 | 505 |

| Applications | General purpose structural applications | Architectural applications | Aerospace, high-strength applications |

Conclusion

6061 aluminum alloy stands out for its combination of strength, lightweight properties, and corrosion resistance, making it a popular choice across various industries. Its versatility in processing and applications ensures it remains a cornerstone material in modern manufacturing and construction.

This outline provides a structured approach to crafting a comprehensive introduction to 6061 Aluminum Alloy, covering its chemical composition, mechanical properties, applications, production standards, processing methods, advantages, disadvantages, and comparison with similar alloys.