5083 Aluminum Precision casting plate

5083 aluminum alloy is an aluminum alloy containing magnesium and trace amounts of manganese and chromium.

It is highly resistant to seawater and industrial chemicals.

Alloy 5083 still has special strength after welding.

It has the highest strength of a non-heat treated alloy with a ultimate tensile strength of 317 MPa or 46,000 psi and a tensile yield strength of 228 MPa or 33,000 psi.

Not recommended for use at temperatures above 65° C

5083 Aluminum Introduction(Corrosion resistant ship plate)

5083 Aluminum The anodized surface of aluminum plate is beautiful. Arc welding has good performance.

The main alloying element in 5083 alloy is magnesium, which has good corrosion resistance, weldability and medium strength.

The excellent corrosion resistance makes 5083 alloy is widely used in Marine applications such as ships, automobile and aircraft welding parts, subway and light rail, pressure vessels requiring strict fire protection (such as liquid tank cars, refrigerated vehicles, refrigerated containers), refrigeration equipment, television towers, drilling equipment, transportation equipment, missile parts, armor, etc.

- 5083 belongs to Al-Mg alloy, which is widely used, especially in construction industry. It is the most promising alloy. Good corrosion resistance, good weldability, good cold working property, and has medium strength.

- The main alloy element of 5083 is magnesium, which has good forming processing performance, corrosion resistance, weldability and medium strength.

- It is used in the manufacture of aircraft fuel tanks, oil pipes, sheet metal parts of traffic vehicles and ships, instruments, street lamp supports and rivets, hardware products, electrical appliance shells and so on.

- Al-Mg alloy, is the most widely used a kind of antirust aluminum, the alloy has high strength, especially with fatigue strength: high plasticity and corrosion resistance, can not be strengthened by heat treatment, in the semi-cold hardening of good plasticity, cold hardening of low plasticity, good corrosion resistance, good weldability, poor cutting performance, can be polished.

- It is mainly used for demanding high plasticity and good weldability, low load parts working in liquid or gas medium, such as oil tank, gasoline or lubricating oil conduit, various liquid containers and other small load parts made by deep drawing: wire is used to do rivets.

Product introduction

5083 Aluminum Alloy Introduction

| Grade | 5083 |

| Status | O / H112 |

| Standard | EN485-2008,GB/T3880-2018 |

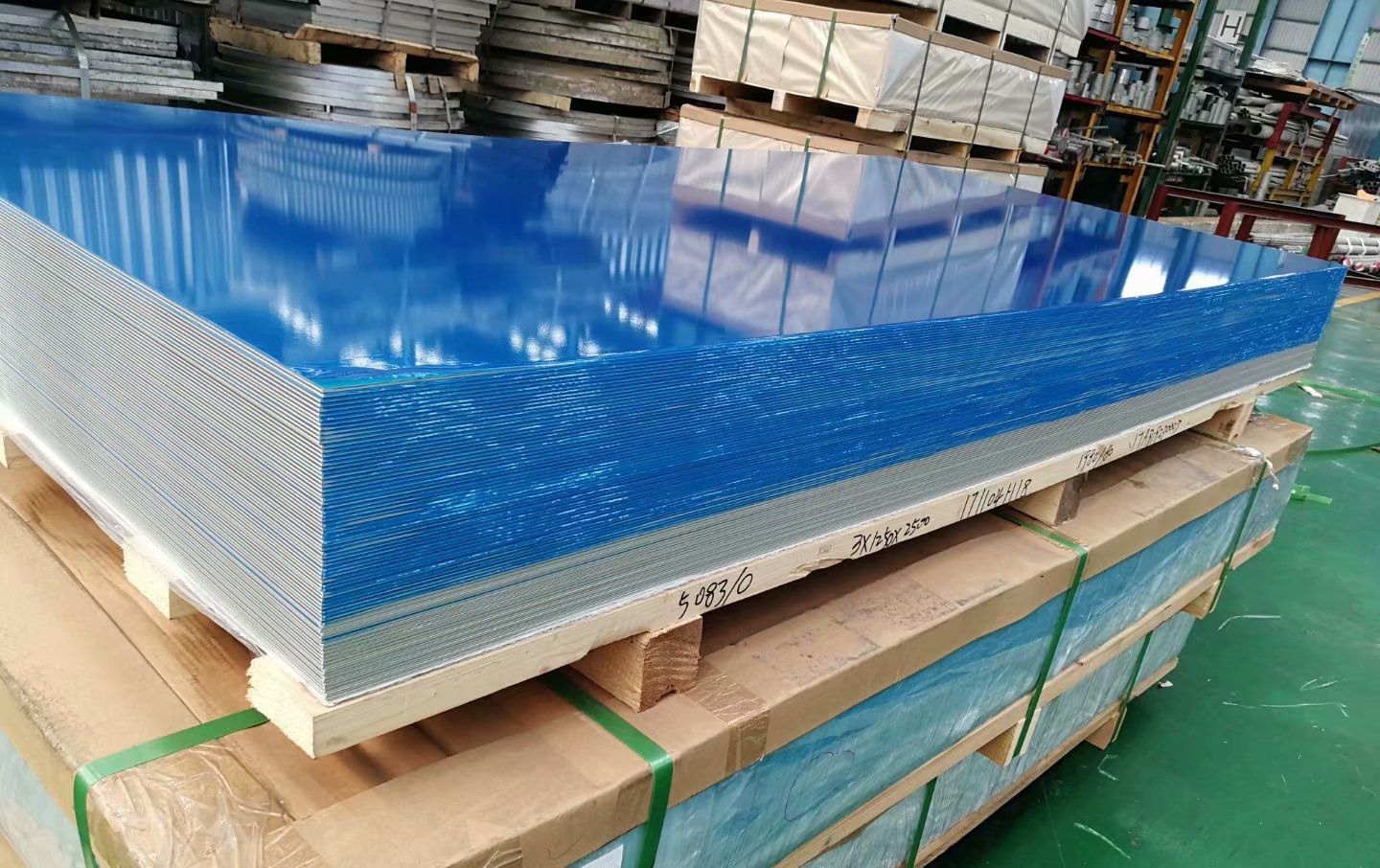

| Size | O: 1-730mm / 1250*2500mm, 1500*3000mm, 2500*5000; H112: 8-120 / 1250*2500mm , 1500*3000mm, 2000*4000 |

| Surface | Cast/hot rolled surface Surface coating of medium thin plate (thickness <100mm) |

The content of trace elements in 5083 is higher, and the hardness is the highest in the non-heat treated alloy.Good resistance to sea water and low temperature, suitable for welding structures with high corrosion resistance.

The content of trace elements in 5083 is higher, and the hardness is the highest in the non-heat treated alloy.Good resistance to sea water and low temperature, suitable for welding structures with high corrosion resistance.

5083 Aluminum Alloy Chemical Composition

Chemical composition table standard (Max)W% | Al: Margin | ||||||

| Si | Fe | Cu | Mn | Mg | Zn | Cr | Ti |

| 0.4 | 0.4 | 0.1 | 0.4-1 | 4-4.9 | 0.25 | 0.05-0.25 | 0.15 |

5083 Aluminum Alloy Mechanical Properties

Mechanical properties table (standard value) | O | H32 | H112 |

| Strength of extension(MPa) | 100-125 | ≥270 | ≥270 |

| Yield strength(MPa) | 215-255 | ≥115 | ≥125 |

| Extend rate(%) | 15-18 | ≥10 | ≥10 |

5083 Aluminum Plate Application

Aluminum alloy 5083 is a high magnesium alloy, which has good strength, corrosion resistance and machinability in non-heat treatment alloy. After anodizing, the surface is beautiful and the performance of arc welding is good.

The main alloying element in 5083 alloy is magnesium, which has good corrosion resistance, weldability and medium strength.

The excellent corrosion resistance makes 5083 alloy is widely used in Marine applications such as ships, automobile and aircraft welding parts, subway and light rail, pressure vessels requiring strict fire protection (such as liquid tank truck refrigerated truck refrigerated container) refrigeration equipment, television towers, drilling equipment, transportation equipment, missile parts and armor, etc.

Alloy Designations

Alloy 5083 also corresponds to: GM41, A95083, AIMg 4.5 Mn and Al Mg 4.5 Mn 0.7.

Temper Types

The most common tempers for 5083 aluminium are: O – Soft, H111 – Some work hardening imparted by shaping processes but less than required fro H11 temper and H32 – Work hardened by rolling then stabilised by low temperature heat treatment to quarter hard.

Fabrication

- Solderability: Poor

- Weldability – Gas: Average

- Weldability – Arc: Excellent

- Weldability – Resistance: Excellent

- Brazability: Poor

- Workability – Cold: Average

- Machinability: Poor

Spot specification

Spot specification of plate: 0.3mm-350mm(thickness)

Bar spot specification: 3.0mm-500mm(diameter)

Wire spot specification: 0.1mm-20mm(wire diameter)

At Lion Metal, we have 26+ years of experience supplying 5083 aluminum forgings, plate, sheet and more to your custom measurements.

Our forging process includes open die forgings, ring rolling and more. See below for a list of common forged shapes, including 5083 round bar and flat bar, as well as additional product forms we offer.

What’s the difference between “5052” and “5083”?

In terms of tensile strength and yield strength, 5083 aluminum plate is much stronger than 5052 aluminum plate.

Their chemical composition is as follows:

5052 Si 0+ Fe 0.45 Cu 0.1 Mn0.1 Mg 2.2-2.8 Cr0.15-0.35 Zn 0.1

5083 Si 0.4 Fe 0.4 Cu 0.1 Mn0.3-1.0 Mg 4.0-4.9 Cr 0.05-0.25 Zn 0.25

Features and uses are as follows:

5052 alloy aluminum plate has good forming processing performance, corrosion resistance, candlability, fatigue strength and medium static strength, used for the manufacture of aircraft fuel tank, oil pipe, and traffic vehicles, ships sheet metal parts, instruments, streetlamp support and rivets, hardware products…

5083 alloy aluminum plate for the need to have high corrosion resistance, good weldability and medium strength of the occasion, such as ship, automobile and aircraft plate welding parts;Fire resistant pressure vessels, refrigerators, television towers, drilling equipment, transportation equipment, missile components, armor…

Note: From the point of view of oxidation, there is little difference between the two, the main difference in mechanical properties.The 5083 Aluminum Alloy Plate has better corrosion resistance and is more suitable for use in harsh environments.

▲ The value is for reference only, different thickness, the value is different.