NIMONIC alloy 81

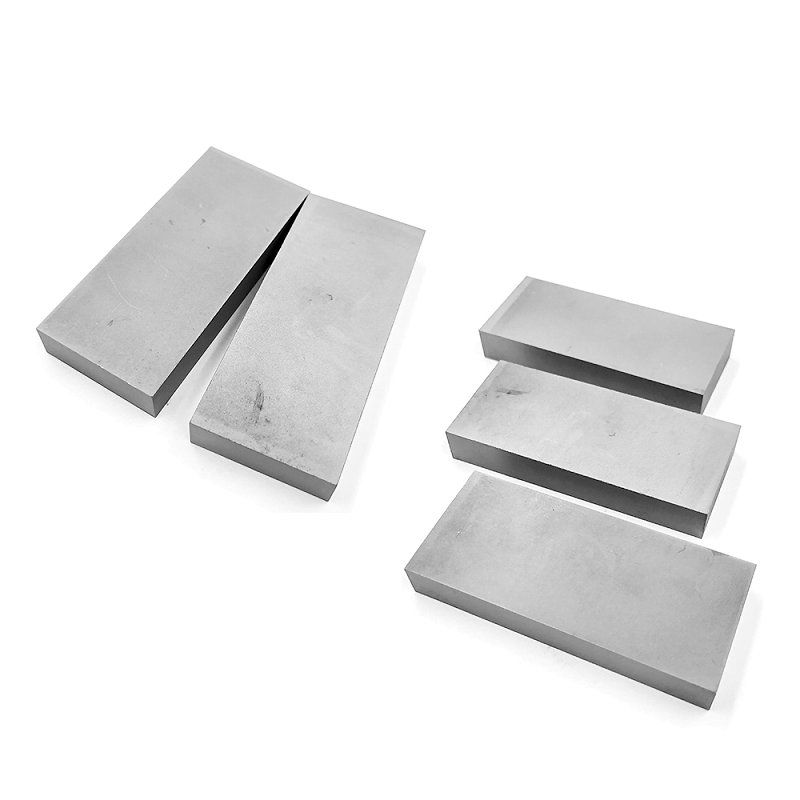

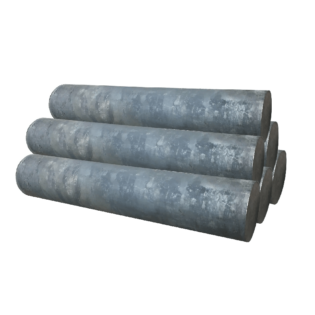

We can produce NIMONIC alloy 81 stainless steel round rods, NIMONIC alloy 81 forging,sheet,coil,and profiledstrip,Deformed steel,flat steel,mould,steel wire,have all specifications. With DuoNian production experience, strict control NIMONIC alloy 81 chemical composition and NIMONIC alloy 81 mechanical properties.From casting, forging, steel to hot and cold rolling process, heat treatment, etc, we have the control of professional engineers. We have advanced precision machining equipment, according to the requirements of users machining. in order to achieve the most satisfied with the user requirements.

Nimonic® 81 Production specification

- Round bar steel: 1mm to 3500mm

- Square-shape steel: 1mm to 4000mm

- Plate steel:0.1mm to 4000mm

- Width: 10mm to 2500mm

Lenth: We can supply any lenth based on the customer’s requirement.

Forging: Shafts with flanks/pipes/tubes/slugs/donuts/cubes/other shapes

Tubings: OD: φ6-1800mm, with wall thickness ranging from 1-35 mm.

Finished goods condition: hot forging/hot rolling + annealing/normalizing + tempering/quenching + tempering/any conditions based on the customer’s requirement

Surface conditions: scaled (hot working finish)/ground/rough machining/fine machining/based on the customer’s requirement

Furnaces for metallurgical processing: electrode arc + LF/VD/VOD/ESR/Vacuum consumable electrode.

Ultrasonic inspection: 100% ultrasonic inspection for any inperfections or based on the customer’s requirementExcellent service for all kinds of industries,with advantages of technologies, equipment and price.

We serve you with our honesty, integrity, and professionality.

Nimonic 81(Nimonic® 81) Nickel Based Superalloy

NIMONIC® 81 and Nimonic 81 is a wrought nickel alloy hardened by controlled additions of titanium and aluminum, and designed to provide enhanced resistance to high temperature corrosion coupled with good high temperature strength. It has excellent hot corrosion resistance due to its high chromium content.

Elevated temperature strength characteristics are similar to those of NIMONIC alloy 80A. Melting, hot-working, cold-working and machining practices are also broadly similar to those for NIMONIC alloy 80A. Applications include components for gas turbines, piston engine exhaust valves, and heat-exchange plant subject to attack by deposits resulting from the combustion of impure fuels, particularly by alkali metal sulfates and chlorides.

Nimonic 81(NIMONIC® 81) is normally used in the solution- and precipitation-treated condition. This heat treatment is generally carried out in air. Material is usually supplied in the solution-treated condition and is aged by the customer as part of the fabrication process. NIMONIC alloy 81 can, however, be supplied to any requested heat-treatment condition. Details of the recommended heat treatments for various forms are given below, where the stated times represent the times at temperature. In establishing furnacing time due allowance must, of course, be made for furnace characteristics and charge weight.

Nimonic 81 Mechanical Properties:

| Material | Ultimate Tensile Strength (MPA) | 0.2 % Yield Strength (MPA) | % Elongation |

|---|---|---|---|

| Nimonic 81 | 874 | 565 | 14 |

Nimonic® 81 Chemical Composition:

| Element | Content (%) |

|---|---|

| Nickel, Ni | 63 |

| Chromium, Cr | ≤30 |

| Cobalt, Co | ≤2 |

| Titanium, Ti | 1.8 |

| Iron, Fe | ≤1.0 |

| Aluminum, Al | 0.9 |

| Others | Remainder |

Nimonic® 81 Physical Properties:

| Properties | Metric | Imperial |

|---|---|---|

| Density | 8.06 gm/cm3 | 0.291 lb/in3 |

Nimonic® 81 Heat Treatment:

Nimonic® 81 Hot working

NIMONIC alloy 81 can be hot worked at temperature ranges of 950-1160°C (1742-2120°F).

Nimonic® 81 Forging

NIMONIC alloy 81 can be hot forged at temperatures in the range of 1010-1176°C (1850-2150°F).

Nimonic® 81 Cold working

Cold working may be done on the alloy for hardening.

Nimonic® 81 Annealing

NIMONIC alloy 81 should be solution annealed at 1098°C (2010°F) for about 8 hours.

Nimonic® 81 Applications

- Heat exchange plant.

- Gas turbine engineering

- Piston engine exhaust valves