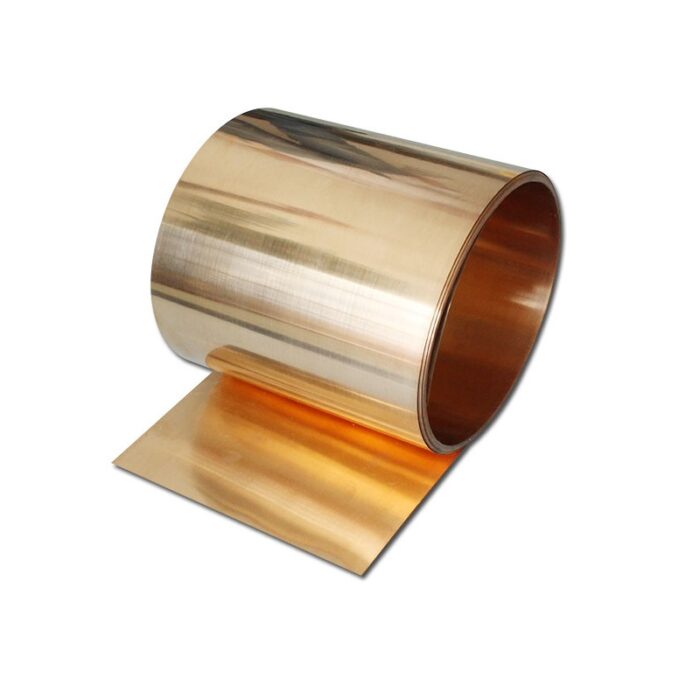

C17200 Beryllium Copper

C17200 beryllium copper, the full range of beryllium copper is called “the king of non-ferrous metal elasticity”.

It is used for all kinds of micro-motor brushes, switches, relays, connectors, temperature With the increasing requirements for the reliability and service life of the springs and various springs of the controller, the demand for beryllium copper will also increase.

C17200 copper’s ultimate tensile and Rockwell hardness properties in a peak aged condition are in the 200 ksi range and RC 45 respectively (electrical conductivity 22% IACS minimum).

Chinese name: C17200 Beryllium Copper

Foreign name: C17200 Beryllium Copper

Nickel Ni: 0.20-0.25

Cobalt Co: 0.35-0.65

Beryllium Be: 1.90-2.15

C17200 Beryllium Copper Description

C17200 Beryllium copper alloy integrates excellent mechanical properties, physical properties and chemical properties.After heat treatment (solution treatment and aging treatment), it has high strength limit, elastic limit, yield limit and fatigue limit equivalent to that of special steel.It also has high electrical conductivity, thermal conductivity, high hardness, corrosion resistance, wear resistance, good casting performance, non-magnetic and non-sparking characteristics, and is widely used in mold manufacturing, machinery, electronics and other industries.No blisters, pores, balanced hardness, dense structure, high strength, good thermal conductivity, good electrical conductivity, corrosion resistance, excellent wear resistance, good processing performance, stable performance under high pressure conditions, non-magnetic, Excellent polishing performance, good anti-adhesion performance.

Use C17200 Beryllium Copper

Injection molds and high pressure blow molds, mold inserts, rapid cooling, aluminum alloy mold inserts, increase strength, wear resistance and shorten the injection cycle, hot runner nozzles, electrodes and punch materials, not affected by magnetic molds, non-magnetic tools , High thermal conductivity bearings, can make mirrors with high surface accuracy.

Commonly used beryllium copper grades are as follows:

- C17200 / C17300 / C17000 are high-strength deformed alloys ;

- C17500 / C17510 are highly conductive deformable alloys;

- BeA-275C/BeA-20C is a high-strength casting alloy ;

- BeA-10C/BeA-50C is a highly conductive casting alloy

C17200 Beryllium Copper Chemical Composition

- Beryllium Be: 1.90-2.15

- Cobalt: 0.35-0.65

- Nickel Ni: 0.20-0.25

- Copper Cu: margin

- Silicon Si: <0.15

- Iron Fe:<0.15

- Aluminum Al: <0.15

- Comparison standard: AISI C17200

C17200 Beryllium Copper Main Performance Index

- Tensile strength (Mpa): 1105

- Specific gravity (g/cm3): 8.3

- Yield strength (0.2%) Mpa: 1035

- Softening temperature (°C):930

- Elongation (%): 1

- Elastic modulus (Gpa): 128

- Hardness (HRC): 38-44

- Thermal conductivity (W/m.k20°C): 105

- Conductivity (IACS%): 18

C17200 Beryllium Copper Performance

- C17200 Beryllium bronze is a precipitation hardening alloy. After solution aging treatment, it has high strength, hardness, elastic limit and fatigue limit, small elastic hysteresis, and has corrosion resistance and processing properties.

- C17200 Beryllium copper alloy is an indispensable submarine cable repeater structure. Alternative materials.

- Wear resistance, low temperature resistance, non-magnetic, high conductivity, impact and no sparks.

- It also has good fluidity and the ability to reproduce fine patterns. Due to the many superior properties of beryllium copper alloy, it has been widely used in the manufacturing industry.

- Strong electrical conductivity, wear resistance, low temperature resistance, non-magnetic, high electrical conductivity, impact and no sparks. It also has good fluidity and the ability to reproduce fine patterns.

- Due to the many superior properties of beryllium copper alloy, it has been widely used in the manufacturing industry.

- The product specifications are complete, the price is favorable, the packaging is intact, the copper is pure, the straightness is good, the inventory is large, and the material certificate and SGS report can be provided.

| Technique | Suitability |

|---|---|

| Soldering | Good |

| Brazing | Good |

| Oxyacetylene Welding | Not Recommended |

| Gas Shielded Arc Welding | Good |

| Coated Metal Arc Welding | Good |

| Spot Weld | Good |

| Seam Weld | Fair |

| Butt Weld | Fair |

| Capacity for Being Cold Worked | Good |

| Capacity for Being Hot Formed | Excellent |

| Forgeability Rating | 40 |

| Machinability Rating | 20 |

C17200 Common Fabrication Processes

- Blanking

- Drawing

- Drilling

- Forming and Bending

- Tapping

- Turning

C17200 Thermal Properties

| Treatment | Minimum* | Maximum* | Value* | Time** | Medium |

|---|---|---|---|---|---|

| * Temperature is measured in Fahrenheit.** Time is measured in minutes. | |||||

| Stress Relief | 400 | ||||

| Solution Treatment | 1425 | 1475 | 0.5 | Water | |

| Precipitation Treatment | 600 | 3 | Air | ||

| Hot Treatment | 1200 | 1500 | |||

| Product Category | Product | Reason Category | Reason |

|---|---|---|---|

| Electrical | Belleville Washers | Corrosion Resistance | Corrosion Resistance |

| Belleville Washers | Forming Characteristics | Formability, Good | |

| Belleville Washers | Mechanical Properties | High Strength | |

| Belleville Washers | Mechanical Properties | Low Elastic Modulus | |

| Clips | Conductivity (Electrical) | Electrical Conductivity | |

| Clips | Conductivity (Thermal) | Thermal Conductivity | |

| Clips | Corrosion Resistance | Corrosion Resistance | |

| Clips | Mechanical Properties | Very High Strength | |

| Connectors | Conductivity (Electrical) | Electrical Conductivity | |

| Connectors | Conductivity (Thermal) | Thermal Conductivity | |

| Connectors | Creep Properties | Creep Resistant | |

| Connectors | Mechanical Properties | Very High Strength | |

| Connectors | Softening Resistance | Resistance to Thermal Softening | |

| Connectors | Thermal Properties | Resistance to Stress Relaxation | |

| Contact Bridges | Conductivity (Electrical) | Electrical Conductivity | |

| Contact Bridges | Conductivity (Thermal) | Thermal Conductivity | |

| Contact Bridges | Corrosion Resistance | Corrosion Resistance | |

| Contact Bridges | Mechanical Properties | Very High Strength | |

| Electrical Switch and Relay Blades | Conductivity (Electrical) | Electrical Conductivity | |

| Electrical Switch and Relay Blades | Forming Characteristics | Formability, Good | |

| Electrical Switch and Relay Blades | Heat Treatability | Heat Treatable | |

| Electrical Switch and Relay Blades | Mechanical Properties | Fatigue Life | |

| Electrical Switch and Relay Blades | Mechanical Properties | High Endurance Limit | |

| Electrical Switch and Relay Blades | Mechanical Properties | High Strength | |

| Electrical Switch and Relay Blades | Thermal Properties | Resistance to Stress Relaxation | |

| Fuse Clips | Conductivity (Electrical) | Electrical Conductivity | |

| Fuse Clips | Conductivity (Thermal) | Thermal Conductivity | |

| Fuse Clips | Corrosion Resistance | Corrosion Resistance | |

| Fuse Clips | Mechanical Properties | Very High Strength | |

| Navigational Instruments | Conductivity (Electrical) | Electrical Conductivity | |

| Navigational Instruments | Conductivity (Thermal) | Thermal Conductivity | |

| Navigational Instruments | Corrosion Resistance | Corrosion Resistance | |

| Navigational Instruments | Mechanical Properties | Very High Strength | |

| Relay Parts | Conductivity (Electrical) | Electrical Conductivity | |

| Relay Parts | Conductivity (Thermal) | Thermal Conductivity | |

| Relay Parts | Corrosion Resistance | Corrosion Resistance | |

| Relay Parts | Mechanical Properties | Very High Strength | |

| Spring Connectors, Current Carrying | Conductivity (Electrical) | Electrical Conductivity | |

| Spring Connectors, Current Carrying | Conductivity (Thermal) | Thermal Conductivity | |

| Spring Connectors, Current Carrying | Corrosion Resistance | Corrosion Resistance | |

| Spring Connectors, Current Carrying | Creep Properties | Creep Resistant | |

| Spring Connectors, Current Carrying | Mechanical Properties | Very High Strength | |

| Spring Connectors, Current Carrying | Softening Resistance | Resistance to Thermal Softening | |

| Spring Connectors, Current Carrying | Thermal Properties | Resistance to Stress Relaxation | |

| Switch Parts | Conductivity (Electrical) | Electrical Conductivity | |

| Switch Parts | Conductivity (Thermal) | Thermal Conductivity | |

| Switch Parts | Corrosion Resistance | Corrosion Resistance | |

| Switch Parts | Creep Properties | Creep Resistant | |

| Switch Parts | Mechanical Properties | Very High Strength | |

| Switch Parts | Softening Resistance | Resistance to Thermal Softening | |

| Fasteners | Bolts | Corrosion Resistance | Corrosion Resistance |

| Bolts | Creep Properties | Creep Resistant | |

| Bolts | Mechanical Properties | Very High Strength | |

| Bolts | Softening Resistance | Resistance to Thermal Softening | |

| Fasteners | Corrosion Resistance | Corrosion Resistance | |

| Fasteners | Mechanical Properties | Toughness | |

| Fasteners | Mechanical Properties | Very High Strength | |

| Lock Washers | Corrosion Resistance | Corrosion Resistance | |

| Lock Washers | Mechanical Properties | Ductility | |

| Lock Washers | Mechanical Properties | Very High Strength | |

| Retaining Rings | Corrosion Resistance | Corrosion Resistance | |

| Retaining Rings | Forming Characteristics | Formability | |

| Retaining Rings | Mechanical Properties | Very High Strength | |

| Roll Pins | Corrosion Resistance | Corrosion Resistance | |

| Roll Pins | Mechanical Properties | Fatigue Resistance | |

| Roll Pins | Mechanical Properties | Very High Strength | |

| Screws | Corrosion Resistance | Corrosion Resistance | |

| Screws | Creep Properties | Creep Resistant | |

| Screws | Mechanical Properties | Very High Strength | |

| Screws | Softening Resistance | Resistance to Thermal Softening | |

| Washers | Corrosion Resistance | Corrosion Resistance | |

| Washers | Mechanical Properties | Very High Strength | |

| Industrial | Bearings | Corrosion Resistance | Corrosion Resistance |

| Bearings | Friction & Wear Properties | Galling Resistance | |

| Bearings | Friction & Wear Properties | Wear Resistance | |

| Bearings | Machining Characteristics | Machinability | |

| Bearings | Mechanical Properties | High Strength | |

| Bellows | Corrosion Resistance | Corrosion Resistance | |

| Bellows | Forming Characteristics | Formability, Good | |

| Bellows | Mechanical Properties | High Strength | |

| Bellows | Mechanical Properties | Low Elastic Modulus | |

| Bourdon Tubes | Corrosion Resistance | Corrosion Resistance | |

| Bourdon Tubes | Forming Characteristics | Formability, Good | |

| Bourdon Tubes | Mechanical Properties | High Strength | |

| Bourdon Tubes | Mechanical Properties | Low Elastic Modulus | |

| Bushings | Corrosion Resistance | Corrosion Resistance | |

| Bushings | Friction & Wear Properties | Galling Resistance | |

| Bushings | Friction & Wear Properties | Wear Resistance | |

| Bushings | Machining Characteristics | Machinability | |

| Bushings | Mechanical Properties | High Strength | |

| Diaphragms | Corrosion Resistance | Corrosion Resistance | |

| Diaphragms | Forming Characteristics | Formability, Good | |

| Diaphragms | Mechanical Properties | High Strength | |

| Diaphragms | Mechanical Properties | Low Elastic Modulus | |

| Flexible Metal Hose | Forming Characteristics | Formability | |

| Flexible Metal Hose | Mechanical Properties | Ductility | |

| Flexible Metal Hose | Mechanical Properties | Very High Strength | |

| Housings for Instruments | Corrosion Resistance | Corrosion Resistance | |

| Housings for Instruments | Machining Characteristics | Machinability | |

| Housings for Instruments | Magnetic Properties | Non-Magnetic | |

| Housings for Instruments | Mechanical Properties | High Strength | |

| Non Sparking Safety Tools | Mechanical Properties | Very High Strength | |

| Non Sparking Safety Tools | Non-Sparking | Non-Sparking | |

| Pump Parts | Corrosion Resistance | Corrosion Resistance | |

| Pump Parts | Forming Characteristics | Formability | |

| Pump Parts | Mechanical Properties | Fatigue Resistance | |

| Pump Parts | Mechanical Properties | Very High Strength | |

| Pumps | Corrosion Resistance | Corrosion Resistance | |

| Pumps | Mechanical Properties | Very High Strength | |

| Rolling Mill Parts | Corrosion Resistance | Corrosion Resistance | |

| Rolling Mill Parts | Forming Characteristics | Formability | |

| Rolling Mill Parts | Friction & Wear Properties | Wear Resistance | |

| Rolling Mill Parts | Mechanical Properties | Fatigue Resistance | |

| Rolling Mill Parts | Mechanical Properties | Very High Strength | |

| Shafts | Corrosion Resistance | Corrosion Resistance | |

| Shafts | Mechanical Properties | Very High Strength | |

| Spline Shafts | Corrosion Resistance | Corrosion Resistance | |

| Spline Shafts | Forming Characteristics | Formability | |

| Spline Shafts | Friction & Wear Properties | Wear Resistance | |

| Spline Shafts | Mechanical Properties | Very High Strength | |

| Springs | Corrosion Resistance | Corrosion Resistance | |

| Springs | Forming Characteristics | Formability | |

| Springs | Mechanical Properties | Fatigue Resistance | |

| Springs | Mechanical Properties | Very High Strength | |

| Springs, Electrochemical | Conductivity (Electrical) | Electrical Conductivity | |

| Springs, Electrochemical | Conductivity (Thermal) | Thermal Conductivity | |

| Springs, Electrochemical | Corrosion Resistance | Corrosion Resistance | |

| Springs, Electrochemical | Mechanical Properties | High Modulus of Elasticity | |

| Valve Seats | Corrosion Resistance | Corrosion Resistance | |

| Valve Seats | Forging Characteristics | Forgability | |

| Valve Seats | Friction & Wear Properties | Galling Resistance | |

| Valve Seats | Friction & Wear Properties | Wear Resistance | |

| Valve Seats | Mechanical Properties | Ductility | |

| Valve Seats | Mechanical Properties | High Strength | |

| Valve Stems | Corrosion Resistance | Corrosion Resistance | |

| Valve Stems | Forging Characteristics | Forgability | |

| Valve Stems | Friction & Wear Properties | Galling Resistance | |

| Valve Stems | Friction & Wear Properties | Wear Resistance | |

| Valve Stems | Mechanical Properties | Ductility | |

| Valve Stems | Mechanical Properties | High Strength | |

| Valves | Corrosion Resistance | Corrosion Resistance | |

| Valves | Forming Characteristics | Formability | |

| Valves | Mechanical Properties | Very High Strength | |

| Wear Plates on Heavy Equipment | Corrosion Resistance | Corrosion Resistance | |

| Wear Plates on Heavy Equipment | Friction & Wear Properties | Galling Resistance | |

| Wear Plates on Heavy Equipment | Friction & Wear Properties | Wear Resistance | |

| Wear Plates on Heavy Equipment | Machining Characteristics | Machinability | |

| Wear Plates on Heavy Equipment | Mechanical Properties | High Strength | |

| Welding Equipment | Conductivity (Electrical) | Electrical Conductivity | |

| Welding Equipment | Conductivity (Thermal) | Thermal Conductivity | |

| Welding Equipment | Corrosion Resistance | Corrosion Resistance | |

| Welding Equipment | Creep Properties | Creep Resistant | |

| Welding Equipment | Mechanical Properties | Very High Strength | |

| Welding Equipment | Softening Resistance | Resistance to Thermal Softening | |

| Ordnance | Firing Pins | Corrosion Resistance | Corrosion Resistance |

| Firing Pins | Mechanical Properties | Very High Strength | |

| Other | Tools | Damping Characteristics | Energy Damping |

| Tools | Impact Resistance | Impact Resistant | |

| Tools | Magnetic Properties | Non-Magnetic | |

| Tools | Mechanical Properties | High Strength | |

| Tools | Non-Sparking | Non-Sparking |

| Form | Specific Sub-Form | Application | System | Standard | Description |

|---|---|---|---|---|---|

| C17200 Bar | AMS | 4533 | COPPER BERYLLINUM ALLOY BARS AND RODS, SOLUTION AND PRECIPITATION HEAT TREATED | ||

| AMS | 4534 | COPPER BERYLLIUM ALLOY BARS AND RODS, SOLUTION HEAT TREATED, COLD WORKED AND PRECIPITATION HEAT TREA | |||

| AMS | 4651 | COPER-BERYLLIUM ALLOY BARS AND RODS, HARD TEMPER | |||

| AMS | 4650 | COPPER-BERYLLIUM ALLOY BARS, RODS AND FORGINGS, SOLUTION HEAT TREATED | |||

| ASTM | B196/B196M | COPPER BERYLLIUM ALLOY ROD AND BAR | |||

| SAE | J463 | WROUGHT COPPER AND COPPER ALLOYS | |||

| ASTM | B194 | COPPER BERYLLIUM ALLOY PLATE, SHEET, STRIP, AND ROLLED BAR | |||

| MILITARY | MIL-C-21657 | COPPER-BERYLLIUM ALLOY, LOW MAGNETIC EFFECT (FOR SPECIAL PURPOSE TOOLS AND EQUIPMENT) | |||

| SAE | J461 | WROUGHT AND CAST COPPER ALLOYS | |||

| C17200 Extrusions | Extrusions | ASTM | B570 | COPPER-BERYLLIUM ALLOY FORGINGS AND EXTRUSIONS | |

| C17200 Forgings | AMS | 4650 | COPPER-BERYLLIUM ALLOY BARS, RODS AND FORGINGS, SOLUTION HEAT TREATED | ||

| Forgings | ASTM | B570 | COPPER-BERYLLIUM ALLOY FORGINGS AND EXTRUSIONS | ||

| C17200 Plate | AMS | 4530 | COPPER-BERYLLIUM ALLOY SHEET, STRIP, AND PLATE – SOLUTION TREATED | ||

| ASTM | B194 | COPPER BERYLLIUM ALLOY PLATE, SHEET, STRIP, AND ROLLED BAR | |||

| C17200 Rod | AMS | 4650 | COPPER-BERYLLIUM ALLOY BARS, RODS AND FORGINGS, SOLUTION HEAT TREATED | ||

| AMS | 4533 | COPPER BERYLLINUM ALLOY BARS AND RODS, SOLUTION AND PRECIPITATION HEAT TREATED | |||

| MILITARY | MIL-C-21657 | COPPER-BERYLLIUM ALLOY, LOW MAGNETIC EFFECT (FOR SPECIAL PURPOSE TOOLS AND EQUIPMENT) | |||

| SAE | J463 | WROUGHT COPPER AND COPPER ALLOYS | |||

| SAE | J461 | WROUGHT AND CAST COPPER ALLOYS | |||

| ASTM | B196/B196M | COPPER BERYLLIUM ALLOY ROD AND BAR | |||

| AMS | 4534 | COPPER BERYLLIUM ALLOY BARS AND RODS, SOLUTION HEAT TREATED, COLD WORKED AND PRECIPITATION HEAT TREA | |||

| AMS | 4651 | COPER-BERYLLIUM ALLOY BARS AND RODS, HARD TEMPER | |||

| C17200 Shapes | AMS | 4650 | COPPER-BERYLLIUM ALLOY BARS, RODS AND FORGINGS, SOLUTION HEAT TREATED | ||

| C17200 Sheet | ASTM | B194 | COPPER BERYLLIUM ALLOY PLATE, SHEET, STRIP, AND ROLLED BAR | ||

| AMS | 4530 | COPPER-BERYLLIUM ALLOY SHEET, STRIP, AND PLATE – SOLUTION TREATED | |||

| AMS | 4532 | COPPER BERYLLIUM ALOY SHEET AND STRIP, HALF-HARD | |||

| C17200 Strip | AMS | 4532 | COPPER BERYLLIUM ALOY SHEET AND STRIP, HALF-HARD | ||

| ASTM | B888/B88M | COPPER ALLOY STRIP FOR USE IN MANUFACTURE OF ELECTRICAL CONNECTORS OR SPRING CONTACTS | |||

| ASTM | B194 | COPPER BERYLLIUM ALLOY PLATE, SHEET, STRIP, AND ROLLED BAR | |||

| SAE | J463 | WROUGHT COPPER AND COPPER ALLOYS | |||

| SAE | J461 | WROUGHT AND CAST COPPER ALLOYS | |||

| AMS | 4530 | COPPER-BERYLLIUM ALLOY SHEET, STRIP, AND PLATE – SOLUTION TREATED | |||

| C17200 Tube | AMS | 4535 | COPPER BERYLLIUM ALLOY MECHANICAL TUBING, SOLUTION AND PRECIPITATION HEAT TREATED | ||

| ASTM | B643 | COPPER-BERYLLIUM ALLOY SEAMLESS TUBE | |||

| C17200 Wire | SAE | J461 | WROUGHT AND CAST COPPER ALLOYS | ||

| ASTM | B197/B197M | COPPER BERYLLIUM ALLOY WIRE | |||

| SAE | J463 | WROUGHT COPPER AND COPPER ALLOYS | |||

| AMS | 4725 | COPPER-BERYLLIUM ALLOY WIRE – SOLUTION HEAT TREATED |