Dillidur 400 Wear Resistant Steel Plate Introduction

Dillidur 400 is an ex-factory wear resistant steel plate with nominal hardness up to 400 HBW.

The Dillidur 400 is recommended for use in high wear environments where good machinability, especially good weldability, is required.

Application examples: earthmoving machinery, loading machinery, dredger, overturning miner, conveying equipment, dump truck, blade, cutting crusher, waste treatment and recovery equipment, etc.

DILLIDUR 400 Description

DILLIDUR 400 V is a wear resistant steel with an average hardness of 400 HBW in delivery condition ex works. Its mechanical properties are achieved by quenching.

DILLIDUR 400 V is preferentially used by the customers where elevated resistance to wear is required together with good workability and especially good weldability.

應用示例:土方移動和裝載機、挖泥機、翻斗車、輸送設備、卡車、切削刃、刀具和破碎機、廢物消除和回收設備。

產品描述

Dillidur 400 Range of application

DILLIDUR 400 V can be delivered in thicknesses from 6 mm (¼ in.) to 150 mm (6 in.), according to the dimensional program. Other dimensions may be possible on request.

化學成分

對於鋼包分析,以下百分比限制值適用:

| C | 和 | 錳 | 磷 | 小號 |

| ≤0.20 | ≤ 0.50 | ≤ 1.80 | ≤0.025 | ≤ 0.010 |

Depending on thickness, the following alloying elements are used singly or in combination for control of full hardening:

| 莫 | 你 | 鉻 | 五 | 鈮 | 乙 |

| ≤ 0.50 | ≤0.80 | ≤ 1.50 | ≤0.08 | ≤0.05 | ≤ 0.005 |

The steel is fully killed and fine-grain treated.

Indicative values for the carbon equivalent:

| Plate thickness [mm] | 10 | 25 | 40 | 80 | 120 |

| 電動汽車 1) | 0.37 | 0.46 | 0.51 | 0.61 | 0.64 |

| 中考 2) | 0.28 | 0.31 | 0.33 | 0.35 | 0.36 |

交貨條件

Controlled water quenched.

1) CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

2) CET = C + (Mn + Mo)/10 + (Cr + Cu)/20 + Ni/40

交貨狀態下的機械性能

硬度

Hardness at room temperature: 370 – 430 HBW

Tensile testing on transverse specimens at room temperature (indicative values for 20 mm (0.8 in.) plate thickness)

Tensile strength 1200 MPa (175 ksi)

Yield point 800 MPa (116 ksi)

Elongation 12 % (lo = 5.65√So)

In spite of their high tensile properties, DILLIDUR steels are not intended for safety relevant components. For this purpose high strength steels DILLIMAX are available.

Charpy-V impact test on longitudinal specimens (indicative values for 20 mm (0.8 in.) plate thickness)

Toughness 30 J at -40 °C (-40 °F)

測試

Brinell surface hardness tested once per heat and 40 t.

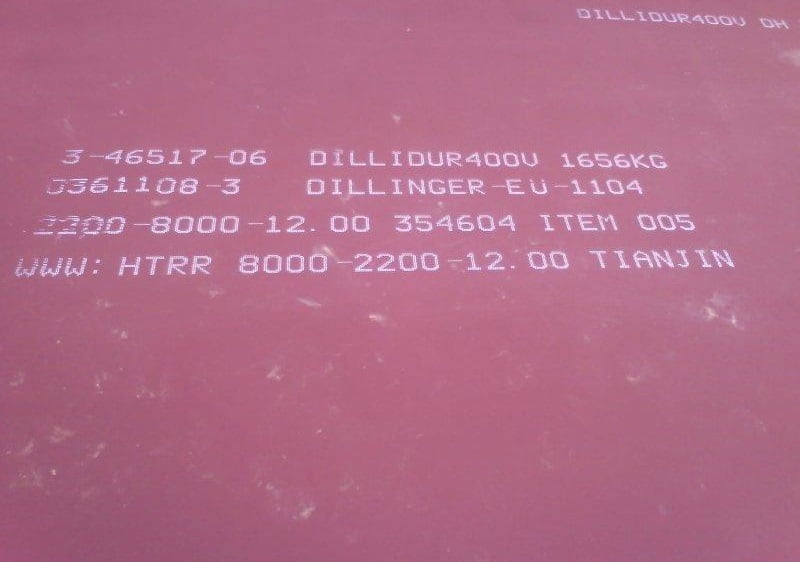

板的識別

Unless otherwise agreed the marking is carried out via steel stamps with at least the following information:

- steel grade (DILLIDUR 400 V)

- 發熱量

- 母板數和單板數

- 製造商的符號

- 檢查員的標誌

Dillidur 400 Processing

The entire processing and application techniques are of fundamental importance to the reliability of the products made from this steel. The user should ensure that his design, construction and processing methods are aligned with the material, correspond to the state-of-the-art that the fabricator has to comply with and are suitable for the intended use. The customer is responsible for the selection of the material. The recommendations in accordance with EN 1011-2 (Welding) and CEN/TR 10347 (Forming) as well as recommendations regarding job safety in accordance with national rules should be observed while considering the higher strength and hardenability.

迪利杜爾 400 Cold forming

DILLIDUR 400 V can be cold formed by bending in spite of its high hardness and strength. It should be paid attention to the fact that with increasing yield strength, the required forces for the forming operation also grow, even if the plate thickness remains unchanged. The spring-back also increases. In order to avoid the risk of cracking from the edges, flame cut or sheared edges should be ground in the area that is to be cold formed. It is also advisable to round the plate edge slightly on the outside of the bend coming under tension stress during bending.

在加工過程中,必須採取必要的安全措施,以免工件在成型過程中可能發生斷裂而造成危險。

通常可以透過冷成型實現以下幾何形狀,而不會形成表面缺陷(其中 t 是板厚度):

| 最小彎曲半徑 | 最小模具開口 | |

| 橫向 | 3噸 | 10 t |

| 縱向 | 4噸 | 12噸 |

迪利杜爾 400 Hot forming

DILLIDUR 400 V obtains its hardness by accelerated cooling from the austenitizing temperature. After hot forming, the same hardness can only be obtained if the steel is quenched again after forming. It is to be expected that the hardness achieved through such a treatment differs from that measured in the delivery condition, because the cooling capacity available during plate manufacturing differs from that available at the fabricator’s works.

The steel may be heated to about 250 °C (482 °F) without a substantial drop in hardness.

Dillidur 400 Flame cutting and welding

For flame cutting, the following minimum temperatures should be observed: 75 °C (170 °F) for plate thicknesses from 30 up to 50 mm, 100 °C (212 °F) for plate thicknesses from 50 up to 100 mm and 150 °C (302 °F) for thicker plates.

For manual arc welding, basic coated rods having a very low residual moisture should be used (if necessary, drying according to the instruction of the manufacturer should be carried out). Additionally the following recommendations are to be considered:

- up to a thickness of 20 mm (0.8 in.) the steel can normally be butt welded without preheating.

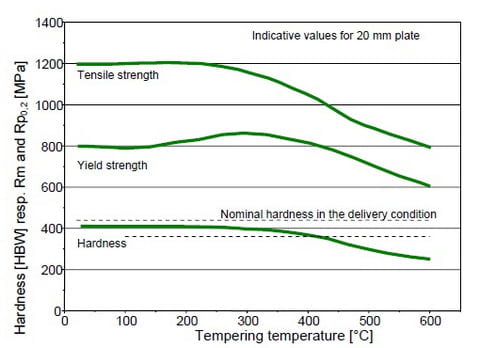

- For more information about preheating of DILLIDUR 400 V, please refer to our technical information “THE CONCEPT TO COMBAT WEAR AND TEAR – DILLIDUR”. A preheating over 250 °C (482 °F) must however be avoided, because it could locally produce a hardness reduction in the base material (see diagram).

- Weld metals with low yield strength are preferred for tack, root and filler passes. If welds are exposed to wear, only the final passes should be welded with consumables producing a hardness matching the parent plate.

Dillidur 400 Heat treatment

The following diagram shows the general changes in hardness or strength values in accordance with the heat treatment temperature:

The following diagram shows the general changes in hardness or strength values in accordance with the heat treatment temperature:

Dillidur 400 Machining

DILLIDUR 400 V can be machined with HSS-drills and especially with HSS-Co-alloyed drills with a satisfactory service life if the drill advance and cutting speed are correspondingly accommodated.

一般技術交付要求

除非另有約定,否則適用符合 EN 10021 的一般技術要求。

公差

Unless otherwise agreed, the tolerances are in accordance with EN 10029, with class A for thickness.

表面質量

Unless otherwise agreed, the provisions in accordance with EN 10163-2, class A2 are applicable.

一般說明

如果有特殊要求且本資料表未涵蓋,請在訂購前聯絡我們並提供規格以供我們審核和同意。本資料表中的資訊是產品描述。此數據表會根據需要進行更新。

For more information about application and processing of DILLIDUR 400 V, please refer to our technical information “THE CONCEPT TO COMBAT WEAR AND TEAR – DILLIDUR”.