Data Table for: Carbon steel: 17NiCrMo6-4

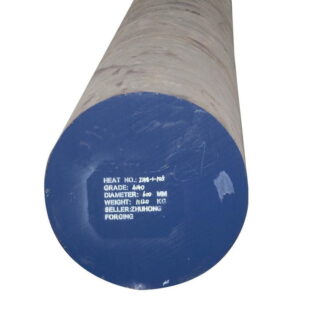

Production specifications: Steel plate, Sheet, Coil, Flat bar, Round bar, Strip steel, wire,All kinds of forgings.

Mchining: Turning, Milling, Grinding

Deep hole drilling: length max 9.8 meters.

Range of work

- Round bar steel: 1mm to 2000mm

- Square-shape steel: 10mm to 1000mm

- steel Plate/sheet:0.08mm to 800mm

- Width: 10mm to 1500mm

- 長さ: お客様の要件に基づいて任意の長さを提供できます。

- Forging: Shafts with flanks, tubes, slugs, donuts, cubes, other shapes

- Tubings: OD: φ4-410 mm, with wall thickness ranging from 1-35 mm.

Heat treatment:

Normalizing, Annealing, Tempering, Quenching, Hardening and tempering, Seasoning, Surface hardening, Carburizing

17NiCrMo6-4鋼丸棒

17NiCrMo6-4 (UNI EN 10084) IS THE NEW DESIGNATION OF 18NiCrMo5 (UNI 7846). IT IS THE MOST COMMON CASE-HARDENING STEEL AND IN EUROPEAN IT IS USED FOR ITS EXCELLENT CHARACTERISTICS THAT MAKE IT SUITABLE FOR SEVERAL APPLICATIONS. IT HAS A MEDIUM-HIGH HARDENABILITY AND A GOOD MACHINABILITY.AFTER CASE-HARDENING AND HARDENING TREATMENTS, THE SURFACE REACHES AN ELEVATED HARDNESS.17NiCrMo6-4 IS USED FOR THE PRODUCTION OF MECHANICAL PARTS, WHICH ARE SUBMITTED TO WEAR (GEARS, CAMSHAFTS, BUSHINGS, PINIONS).IS USED FOR THE PRODUCTION OF MECHANICAL PARTS, WHICH ARE SUBMITTED TO WEAR (GEARS, CAMSHAFTS, BUSHINGS, PINIONS).

- Other Recommended Materials: 20CrNiMo

CORRESPONDENCE TO INTERNATIONAL DESIGNATIONS

| QUALITY | EUROPE | GERMANY | FRANCE | SPAIN | G.B. | アメリカ合衆国 | |

|---|---|---|---|---|---|---|---|

| で | から | W.n. | AFNOR | あ | B.S. | AISI/SAE | |

| 17NiCrMoS6-4 | 17NiCrMoS6-4 | 1.6566 | 18NCD6 | 817M17 | 4317 | ||

17NiCrMo6-4 CHEMICAL COMPOSITION % (EN 10084)

| STEEL DESIGNATION | CHEMICAL COMPOSITION | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SYMBOLIC | NUMERIC | C | そして max | ん | P max | S | Cr | モー | で | B |

| 17NiCrMo6-4 | 1,6566 | 0,14 ÷ 0,20 | 0,40 | 0,60 ÷ 0,90 | 0,025 | ≤ 0,035 | 0,80 ÷ 1,10 | 0,15 ÷ 0,25 | 1,20 ÷ 1,50 | – |

| 17NiCrMoS6-4 | 1,6569 | 0,020 ÷ 0,040 | ||||||||

CONCENTRATION LIMITS OF THE ELEMENTS THAT ARE NOT INDICATED IN THE TABLE CAN BE DEDUCED IN THE EN 10020 REGULATION. IT CAN BE PROVIDED WITH AN ADDITION OF LEAD 0,12-0,35% OR SULPHUR CONTROLLED UP UNTIL 0,40% FOR AN IMPROVED MACHINABILITY.

MECHANICAL CHARACTERISTICS (UNI 7846)

| STEEL QUALITY | BAR’S DIAMETER | TENSILE TESTING | IMPACT STRENGTH KCU min | ||||

|---|---|---|---|---|---|---|---|

| UNIFIED TENSILE STRENGTH R | DEVIATION FROM PROPORTIONALITY Rp 0,2 分 | ELONGATION A min | |||||

| んん | N/mm2 | kgf/mm2 | N/mm2 | kgf/mm2 | % | J | |

| 18NiCrMo5 | 11 (30) (63) | 1230÷1520 (980÷1270) (830÷1130) | 125÷155 (100÷130) (85÷115) | 980 (735) (635) | 100 (75) (65) | 8 (9) (10) | 30 (32,5) (35) |

JOMINY HARDENABILITY (EN 10084)

| STEEL DESIGNATION | RANGE LIMITS | HRC HARDNESS MEASURED FROM THE QUENCHED END OF THE TEST TUBE (MM) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SYMBOLIC | NUMERIC | 1,5 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | |

| 17NiCrMo6-4+H | 1.6566+H | max | 47 | 47 | 46 | 45 | 43 | 42 | 41 | 39 | 37 | 35 | 34 | 34 | 33 |

| 17NiCrMoS6-4+H | 1.6569+H | 分 | 39 | 38 | 36 | 35 | 32 | 30 | 28 | 26 | 24 | 22 | 21 | 20 | 20 |

| 17NiCrMo6-4+HH | 1.6566+HH | max | 47 | 47 | 46 | 45 | 43 | 42 | 41 | 39 | 37 | 35 | 34 | 34 | 33 |

| 17NiCrMoS6-4+HH | 1.6569+HH | 分 | 42 | 41 | 39 | 38 | 36 | 34 | 32 | 30 | 28 | 26 | 25 | 25 | 24 |

| 17NiCrMo6-4+HL | 1.6566+HL | max | 44 | 44 | 43 | 42 | 39 | 38 | 37 | 35 | 33 | 31 | 30 | 29 | 29 |

| 17NiCrMoS6-4+HL | 1.6569+HL | 分 | 39 | 38 | 36 | 35 | 32 | 30 | 28 | 26 | 24 | 22 | 21 | 20 | 20 |

USUALLY AVAILABLE EX STOCK

| QUALITY | 熱処理 | SURFACE | |

|---|---|---|---|

| 17NiCrMo6-4 | Soft-annealed | rolled forged turned drawn / peeled h111 | |

| 17NiCrMo6-4 high machinability | Soft-annealed | rolled peeled | |

| 17NiCrMo6-4+PB | Soft-annealed | rolled drawn / peeled h111 |