Dillidur 500 Description

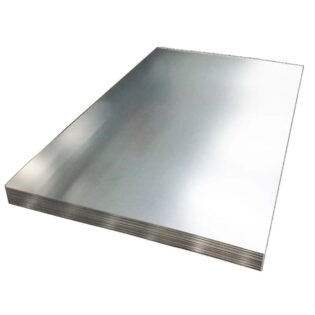

Dillidur 500 is a wear-resistant steel plate with a nominal hardness of 500 HBW in the delivery state.

Dillidur 500 is recommended for applications in extremely high-wear environments where materials are required to have excellent machinability, especially excellent welding performance.

用途例:土木機械、積込機械、浚渫船、ダンプトラック、搬送装置、ダンプトラック、ブレード、カットオフクラッシャー、廃棄物処理・リサイクル装置など。

Dillidur 500 Wear-Resistant Steel Plate

DILLIDUR 500 is a wear-resistant steel plate with a nominal hardness of 500 HBW in the delivery state.

DILLIDUR 500 is recommended for applications in extremely high-wear environments where materials are required to have excellent machinability, especially excellent welding performance.

用途例:土木機械、積込機械、浚渫船、ダンプトラック、搬送装置、ダンプトラック、ブレード、カットオフクラッシャー、廃棄物処理・リサイクル装置など。

DILLIDUR 500 Product Description

Supply size range

According to the supply outline, DILLIDUR 500 is available in thicknesses from 8mm (1/3 inch) 2 ~100mm(4インチ) 2 . Other size requirements can be discussed separately.

DILLIDUR 500 Chemical Composition:

製錬分析に基づいて、次の限界値 (%) が各成分に適用されます。

| C | そして | ん | P | S |

| ≤ 0.30 | ≤ 0.70 | ≤ 1.60 | ≤ 0.025 | ≤ 0.010 |

厚さに応じて、次の合金元素の 1 つ以上が追加されます。

| モー | で | 銅 | Cr | V | 注意 | B |

| ≤ 0.50 | ≤ 1.0 | ≤ 0.30 | ≤ 1.50 | ≤ 0.08 | ≤ 0.05 | ≤ 0.005 |

溶鋼は完全に沈静化され、細粒化のために処理されます。

炭素換算基準値:

ある CEV =C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

b CET =C+(Mn+Mo)/10+(Cr+Cu)/20+Ni/40

1 The content of this information is a product description, and may be updated from time to time.

2 The approximate conversion value in parentheses is an offensive reference.

配送状況:

温度制御水焼入れ

出荷状態での機械的特性

硬度

Brinell hardness of surface at room temperature:

Board thickness ≤ 30mm (1.2 inches) 3 , 470-530 HBW

Board thickness> 30mm (1.2 inches) 3 , 450-530 HBW

室温における横断試験片の引張試験(厚さ20mmの鋼板の参考値)

Tensile strength: 1600 MPa (232 ksi) 3

Yield point: 1100 MPa (160 ksi) 3

Elongation: 9% (L ああ = 5.65 √S ああ )

Although ディリドゥル has high tensile properties, it is not suitable for applications that emphasize safety. In this case, please use high-strength steel ディリマックス。

縦試験片 Vノッチシャルピー衝撃試験(厚さ20mm鋼板の参考値)

Charpy impact energy: 25 J at -20°C (-4°F) 3

The Brinell hardness of the test surface is tested every furnace and every 40 tons.

鋼板マーク

他に取り決めがない場合、鋼板マークには少なくとも次の内容を含める必要があります。

- Grade (DILLIDUR 500)

- 炉番号

- マザーボード番号とスチールプレート番号

- 製鉄所の看板

- 検査官の署名

DILLIDUR 500 Processing performance

The whole set of processing technology and application technology adopted by the user is very important to the reliability of the products made from this material. It should be ensured that the design, construction and processing methods are suitable for this material, and meet the requirements of the latest processing technology and the purpose of the product that the processor must follow. The user should select the material by himself, and fully consider the high strength and high hardness of the material, and follow the process recommendations that comply with EN 1011-2 (welding) and CEN/TR 10347 (forming), and comply with national regulations for safe production.

3 The approximate conversion value in parentheses is an offensive reference.

冷間成形

Although DILLIDUR 500 has high hardness and high strength, it can still be cold formed by bending. It should be noted that as the yield strength increases, the forming force required for the steel plate of the same thickness will also increase, and the resilience will also increase. In order to avoid the risk of edge cracking, the flame cut or sheared edge of the cold bending area should be polished. In addition, it is also recommended to smoothly polish the outer edge of the bend that is subjected to tensile stress during bending.

成形中に作業者がワークピースから飛び散る危険にさらされないよう、加工中は必要な安全対策を講じる必要があります。

冷間成形では、通常、表面欠陥なしで次のパラメータを達成できます (t は板厚です)。

| 最小曲げ半径 | 最小型開口幅 | |

| 水平 | 7 t | 16 t |

| 垂直 | 9 t | 20 t |

の硬さ 熱間成形 DILLIDUR 500 comes from the accelerated cooling of the austenitizing temperature. If the hardness does not decrease significantly after hot forming, it must be supplemented by subsequent re-quenching treatment. However, the hardness obtained after re-quenching will be different from the hardness tested when the steel plate leaves the factory. This is because the cooling efficiency of the quenching equipment in the processing plant is generally lower than that of the quenching equipment during the production of steel plates.

This material can be heated to about 200°C (390°F) without a significant decrease in hardness.

火炎切断と溶接

Flame cutting should follow the following minimum preheating temperature: plate thickness 26mm and below, 60°C (140°F);

plate thickness 26~70mm and below, 120°C (248°F); plate thickness above 70mm , 150°C (302°F).

手動アーク溶接では、残留水分の少ないアルカリ被覆電極を使用する必要があります (必要に応じて、電極メーカーの要件に従って乾燥処理を実行する必要があります)。

さらに、次の提案も考慮する必要があります。

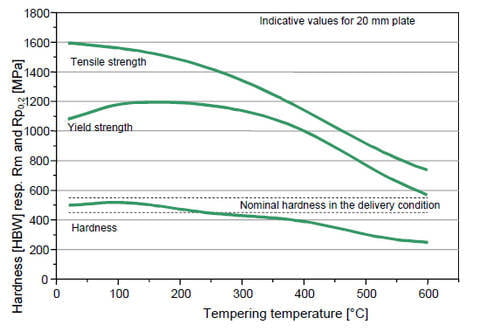

- For more information on the preheating of DILLIDUR 500, please refer to the technical manual “DILLIDUR-Anti-wear concept”. In any case, preheating above 200 °C (390 °F) must be avoided because it will cause the hardness to decrease (see the figure below).

- It is best to use low yield strength welding consumables for tack welding, root bead and filler bead. If the welding point needs to withstand wear, only use the wear-resistant welding material that can produce the hardness of the mother board in the last weld pass.

熱処理

The following figure shows the general change in hardness or strength with heat treatment temperature:

The following figure shows the general change in hardness or strength with heat treatment temperature:

機械加工

DILLIDUR 500 can use high-speed steel drills, especially cobalt alloy high-speed drills. If the appropriate drilling speed and drilling speed are used, the drill bit can achieve a satisfactory service life.

一般的な納品の技術要件

別段の合意がない限り、一般的な配信テクノロジーでは EN 10021 規格を使用する必要があります。

許容範囲

別段の合意がない限り、公差要件は EN 10029 を参照し、厚さは A レベルに適用されます。

表面品質

別段の合意がない限り、EN 10163-2 規格を参照し、A2 レベルを適用します。

合計音符

使用目的またはフォローアッププロセスの理由により、本書に記載されていない材料に関するその他の特別な要件がある場合は、注文前に交渉することができます。

この情報の内容は製品の説明であり、随時更新される場合があります。

For more detailed information on the application and processing of DILLIDUR 500, please refer to the technical manual “DILLIDUR-Anti-wear concept”.