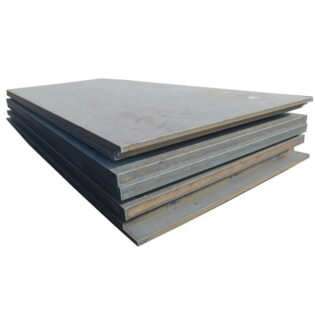

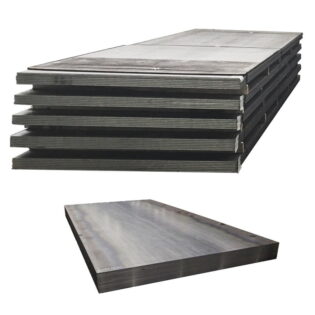

Dillidur 550 耐摩耗鋼板

Dillidur 550 is a wear-resistant steel plate with a nominal hardness of 550 HBW in the delivery state.

Dillidur 550 can be used in high-strength wear environments.

Application examples: extremely worn parts of earth-moving machinery, conveying equipment, crushers and waste recycling equipment.

Dillidur 550 耐摩耗鋼板

Dillidur 550 is a wear-resistant steel plate with a nominal hardness of 550 HBW in the delivery state.(DILLINGER)

ディリドゥル 550 can be used in high-strength wear environments.

Application examples: extremely worn parts of earth-moving machinery, conveying equipment, crushers and waste recycling equipment.

Dillidur 550 PDF DOWNLOAD

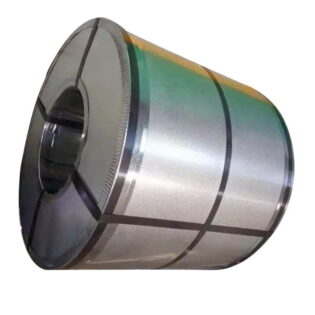

Supply Size Range

ディリドゥル 550 is available in thicknesses from 10mm (0.4 inches) to 51mm (2 inches) and widths below 3300mm (130 inches) 2 。

ディリドゥル 550 Chemical Composition:

Based on smelting analysis, the following limit values(%) are applicable to each component

| C | そして | ん | P | S |

| ≤ 0.37 | ≤ 0.70 | ≤ 1.60 | ≤ 0.025 | ≤ 0.010 |

厚さに応じて、次の合金元素の 1 つ以上が追加されます。

| モー | で | 銅 | Cr | V | 注意 | B |

| ≤ 0.60 | ≤ 1.40 | ≤ 0.30 | ≤ 1.50 | ≤ 0.08 | ≤ 0.05 | ≤ 0.005 |

溶鋼は完全に沈静化され、細粒化のために処理されます。

1 The content of this information is a product description, and may be updated from time to time.

2 The conversion value of myopia in parentheses is an offensive reference.

炭素換算基準値:

| CEV ある | 0.70 |

| 中央ヨーロッパ時間 b | 0.50 |

ある CEV =C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

b CET =C+(Mn+Mo)/10+(Cr+Cu)/20+Ni/40

配送状況:

The steel plate is quenched by temperature controlled water or water quenched + tempered.

出荷状態での機械的特性

硬度

Surface Brinell hardness at room temperature: 520-580 HBW

Longitudinal specimen V-notch Charpy impact test (reference value for 20mm thick steel plate):

Charpy impact energy: 25 J at -20°C (-4°F) 3

テスト

表面ブリネル硬度は テストされた すべての炉と 40 トンごとに。

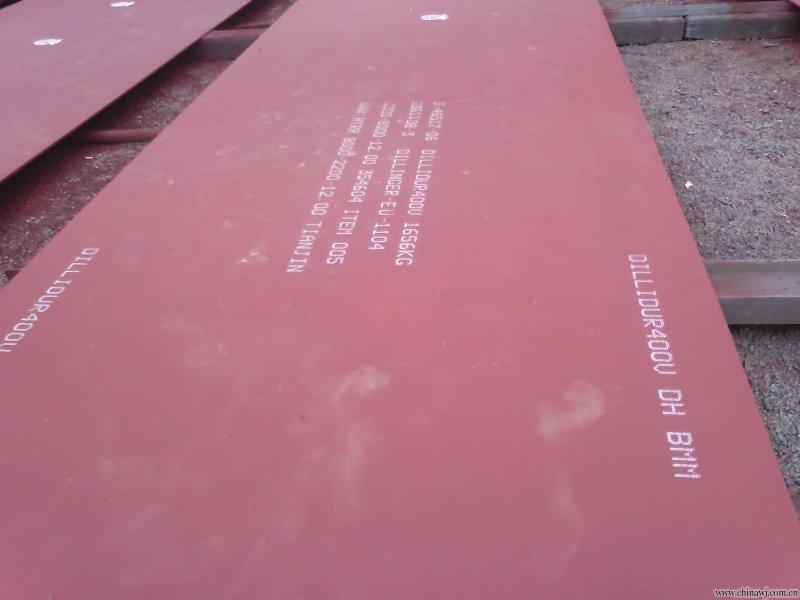

鋼板マーク

他に取り決めがない場合、鋼板マークには少なくとも次の内容を含める必要があります。

- Grade (DILLIDUR 550)

- 炉番号

- マザーボード番号とスチールプレート番号

- 製鉄所の看板

- Inspection representative label

3 括弧内のほぼ換算値は参考値です。

Processing performance

The whole set of processing technology and application technology used by the user is very important to the reliability of the product made from this material. It should be ensured that the design, structure and processing method are suitable for this material and meet the latest processing requirements and the purpose of the product that the processor must follow. Purpose requirements. The user should select the material by himself, and fully consider the high strength and high hardness of the material, and follow the process recommendation that meets the national standards for safe production.

冷間成形

Although DILLIDUR 550 is too high in hardness and strength, the room for cold forming is limited, and you must consult in advance.

の硬さ hot forming/heat treatment DILLIDUR 550 comes from accelerated cooling from the austenitizing temperature. If the hardness does not decrease significantly after hot forming, it is possible to supplement the subsequent re-quenching treatment. However, the hardness obtained after re-quenching will be different from the hardness tested when the steel plate leaves the factory. This is because the cooling efficiency of the quenching equipment in the processing plant is generally lower than that of the quenching equipment during the production of steel plates.

This material can be heated to about 250°C (482°F) without a significant decrease in hardness.

Flame cutting and welding:

For all thickness steel plates, the following minimum preheating temperature should be followed during flame cutting: 175°C (347°F)

After flame cutting, measures should be taken to maintain slow cooling. For example, insulation wool can be used, which will reduce the risk of hydrogen-induced cracking.

When using ferritic welding consumables, care should be taken to select very low hydrogen content welding consumables and follow the following preheating temperature: 150°C (302°F) for thickness 15mm and below; 200°C (392°F) for thickness above 15mm F)

When using soft austenitic welding consumables, the preheating temperature of 50°C (122°F) is usually sufficient.

In order to avoid the decrease in hardness, the preheating temperature and interlayer temperature corresponding to flame cutting and welding should not exceed 250°C (482°F).

Manual arc welding should use alkaline-coated electrodes with residual moisture in the ground (if necessary, they should be dried according to the requirements of the electrode manufacturer).

機械加工

Despite its extremely high hardness, DILLIDUR 550 can still be machined by using sharp carbide tools. It is necessary to ensure that a heavy-duty processing machine tool is used, and an appropriate feed speed and cutting speed are used.

一般的な納品の技術要件

別段の合意がない限り、一般的な配信テクノロジーでは EN 10021 規格を使用する必要があります。

許容範囲

別段の合意がない限り、公差要件は EN 10029 を参照し、厚さは A レベルに適用されます。

表面品質

別段の合意がない限り、EN 10163-2 規格を参照し、A2 レベルを適用します。

合計音符

使用目的またはフォローアッププロセスの理由により、本書に記載されていない材料に関するその他の特別な要件がある場合は、注文前に交渉することができます。