Dillimax 690 耐磨鋼板

- DILLIMAX 690 is a high strength quenched and tempered, fine grained structural steel with a minimum yield strength of 690 MPa (100 ksi)2) in its delivery condition (referring to the lowest thickness range). Its mechanical properties are achieved by water quenching followed by tempering.

- DILLIMAX 690 is preferentially used for welded steel structures within mechanical constructions, plant constructions and structural steel works, such as machines for structural engineering, conveying plants, hoists, cranes, flood gates, bridges and frameworks.

DILLIMAX 690 can be delivered in three qualities:

- Basic (B) with minimum impact values down to -20 °C (-4 °F)2) : DILLIMAX 690 B

Steel number 1.8931 – S690Q according to EN 10025-6 - Tough (T) with minimum impact values down to -40 °C (-40 °F)2) : DILLIMAX 690 T

Steel number 1.8928 – S690QL according to EN 10025-6 - Extra tough (E) with minimum impact values down to -60 °C (-76 °F)2) : DILLIMAX 690 E

Steel number 1.8988 – S690QL1 according to EN 10025-6, only up to a plate thickness of 200 mm

DILLIMAX 690 Wear Resistant Steel Plate

DILLIMAX 690 is a high strength quenched and tempered, fine grained structural steel with a minimum yield strength of 690 MPa (100 ksi)2) in its delivery condition (referring to the lowest thickness range).

Its mechanical properties are achieved by water quenching followed by tempering.

DILLIMAX 690 is preferentially used for welded steel structures within mechanical constructions, plant constructions and structural steel works, such as machines for structural engineering, conveying plants, hoists, cranes, flood gates, bridges and frameworks.

產品描述

名稱和應用範圍

DILLIMAX 690 can be delivered in three qualities:

- 基礎(B) 影響值最低可達 -20 °C (-4 °F)2) : DILLIMAX 690 B

Steel number 1.8931 – S690Q according to EN 10025-6 - 堅韌(T) 最小影響值低至 -40 °C (-40 °F)2) : DILLIMAX 690 T

Steel number 1.8928 – S690QL according to EN 10025-6 - 超強韌 (E) 最小影響值低至 -60 °C (-76 °F)2) : DILLIMAX 690 E

Steel number 1.8988 – S690QL1 according to EN 10025-6, only up to a plate thickness of 200 mm

DILLIMAX 690 can be delivered as basic grade (B) or tough grade (T) in thicknesses from 6 to 250 mm (¼ to 10 in.)2), as extra tough grade (E) in thicknesses from 6 to 200 mm (¼ to 8 in.)2) according to the dimensional program.

Dimensions, which deviate from the usual dimensional program, may be possible on request.

DILLIMAX 690 fulfils the requirements of EN 10025-6.

DILLIMAX 690 Chemical composition

For the ladle analysis, the following limiting values in % are applicable :

| DILLIMAX 690 | C | 和 | 錳 | 磷 | 小號 | 鉻 | 你 | 莫 | 釩+鈮 | 乙 | |

| 乙、乙、乙 | t ≤ 200 mm | ≤0.20 | ≤ 0.50 | ≤1.60 | ≤ 0.020 | ≤ 0.010 | ≤ 1.50 | ≤ 1.80 | ≤ 0.60 | ≤0.10 | ≤0.004 |

| B, T | t > 200 mm | ≤0.18 | ≤ 2.60 | ≤ 0.70 | |||||||

透過足夠的鋁含量,鋼的晶粒細化。

限制 CEV3) values are lower than the values given in EN 10025-6 :

| Plate thickness t [mm] (in.) A) | DILLIMAX690 最大限度。 CEV [%] | See EN 10025-6 最大限度。 CEV [%] |

| t ≤ 25 (1) | 0.50 | 0.65 |

| 25 (1) < t ≤ 50 (2) | 0.55 | 0.65 |

| 50 (2) < t ≤ 100 (4) | 0.67 | 0.77 |

| 100 (4) < t ≤ 150 (6) | 0.75 | 0.83 |

| 50 (6) < t ≤ 250 (10) | 0.78 | – |

A) 括號中的近似轉換值僅供參考

可依要求商定較低的碳當量值。

1) 該材料數據表的當前版本也可以在 http://www.dillinger.de.

2) The approximately converted values in brackets are for information only.

3) CEV = C +Mn/6 +(Cr+Mo+V)/5 + (Cu+Ni)/15

DILLIMAX 690 交貨條件

依 EN 10025-6 進行水淬和回火。

交貨狀態下的機械和技術性能

環境溫度下的拉伸試驗——橫向試樣——

| 板厚 | 抗拉強度 | 最小屈服強度 | 最小伸長率 | ||

| t [毫米](英吋) A) | R米 [兆帕] (ksi) A) | ReHb) [兆帕] (ksi) A) | 一種5個 [%] | 一種2吋。C) [%] | |

| ≤ 65 (2.5) | 770 – 940 (112 – 136) | 690 (100) | 14 | 15 | |

| > 65 (2.5) | ≤ 100 (4) | 770 – 940 (112 – 136) | 670 (97) d) | ||

| > 100 (4) | ≤ 150 (6) | 720 – 900 (104 – 130) d) | 630 (91) d) | ||

| > 150 (6) | ≤ 200 (8) | 700 – 880 (102 – 128) d) | 610 (88) d) | ||

| > 200 (8) | ≤ 250 (10) | 690 – 870 (100 – 126) d) | 600 (87) d) | ||

A) The approximately converted values in brackets are for information only.

b) 如果不明顯,屈服強度 Rp0.2 而是進行測量。

C) 如果根據 ASTM A370 進行測試,則這些值適用。

d) Higher minimum values may be agreed on request. For Offshore applications special grades are available.

DILLIMAX 690 Impact test on Charpy-V-specimens

| DILLIMAX 690 | 試樣方向 | Impact energy Av [J] (ft.-lb.) A) 在測試溫度 | |||

| 0 °C (32 °F) a) | -20°C (-4°F) A) | -40 °C(-40 °F) A) | -60°C(-76°F) A) | ||

| 基礎(B) | 縱向/橫向 | 40/30 (30/22) | 30/27 (22/20) | - | - |

| 高韌性(T) | 縱向/橫向 | 50/35 (37/26) | 40/30 (30/22) | 30/27 (22/20) | - |

| 超強韌 (E)b) | 縱向/橫向 | 60/40 (44/30) | 50/35 (37/26) | 40/30 (30/22) | 30/27 (22/20) |

A) The approximately converted values in brackets are for information only.

b) The extra tough grade E according to this data sheet is only available up to a plate thickness of 200 mm. Enhanced impact energy requirements can be agreed upon request. For Offshore applications special grades are available.

The specified minimum value is the average of 3 tests. One individual value may be below the minimum average value specified, provided that it is not less than 70 % of that value. For plate thicknesses below 12 mm, the test can be carried out on Charpy-V test pieces with reduced width; the minimum width must be 5 mm. The minimum impact value will be decreased proportionally.

DILLIMAX 690 Testing

Tensile and impact tests will be performed according to EN 10025-6 once per heat and 40 t.

Tests on every heat treated plate may be possible on request. The test pieces are taken and prepared according to part 1 and 6 of EN 10025.

拉伸試驗在標距長度 L 的試樣上進行這 = 5.65⋅√S這 分別為 L這 = 5⋅d這, in accordance with EN ISO 6892- 1. Tensile tests according to ASTM A370 may be agreed. The impact test will be carried out on Charpy-V-specimens in accordance with EN ISO 148-1 using a 2 mm striker. Unless otherwise agreed, the test will be performed at the lowest temperature of the corresponding quality on transverse test pieces.

除非另有約定,否則測試結果記錄在符合 EN 10204 的檢驗證書 3.1 中。

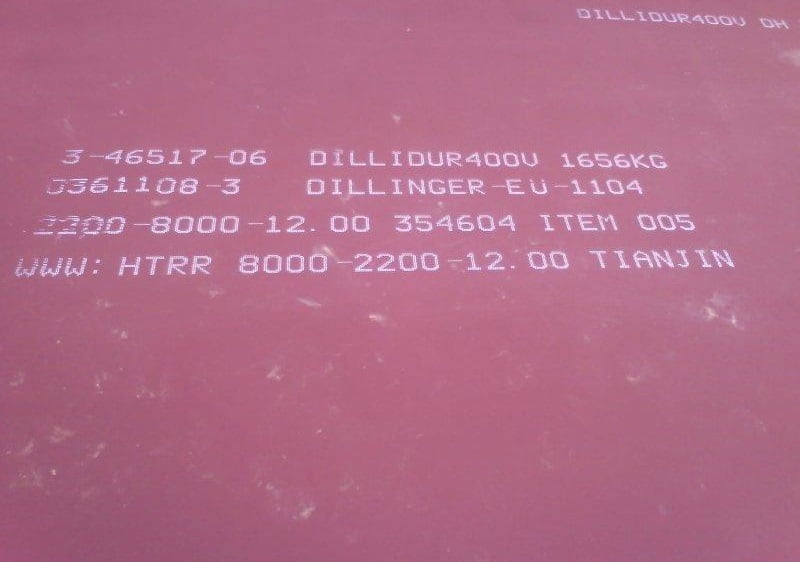

板的識別

除非另有約定,標記透過鋼印進行,至少包含以下資訊:

- steel grade (e.g. DILLIMAX 690 B, T or E)

- 發熱量

- 母板數和單板數

- 製造商的符號

- 授權檢驗代表簽字

加工

The entire processing and application techniques are of fundamental importance to the reliability of products made from this steel. The user should ensure that his design, construction and processing methods are aligned with the material, correspond to the state-of-the-art that the fabricator has to comply with and are suitable for the intended use. The customer is responsible for the selection of the material.

The recommendations of the EN 1011-2 (Welding) and CEN/TR 10347 (Forming) as well as recommendations regarding job safety in accordance with national rules should be observed.

DILLIMAX 690 Cold forming

冷成型是指在低於最大允許應力消除溫度 (560 °C/1040 °F) 的情況下成型4).

DILLIMAX 690 can be cold formed with regard to its high yield strength. Flame cut or sheared edges in the bending area should be ground before cold forming. Cold forming is related to a hardening of the steel and to a decrease in toughness. Some codes may limit the maximum permissible strain during cold forming.

Depending on the relevant code this can result in the need of larger bending radiuses than indicated in the chart. For larger cold forming amounts we recommend you to consult the steel producer prior to ordering.

在加工過程中,必須採取必要的安全措施,以免工件在成型過程中可能發生斷裂而造成危險。

通常可以透過冷成型實現以下幾何形狀,而不會形成表面缺陷(其中 t 是板厚度):

| 最小彎曲半徑 | 最小模具寬度 | |

| 橫向 | 2 t | 7噸 |

| 縱向 | 3噸 | 9噸 |

DILLIMAX 690 Hot forming

若溫度為 560 °C (1040 °F)4) is exceeded, the initial tempering will be altered so that the mechanical properties are affected.

To regain the initial properties new quenching and tempering become necessary. However, water quenching of a formed workpiece or component will often be less effective than the original quenching in the plate mill so that the fabricator may not be able to reestablish the properties required and therefore hot forming may not be suitable.

In this respect we recommend you to contact the steel producer prior to ordering, in all cases where hot forming is required.

最後,製造商有責任通過適當的熱處理獲得所需的鋼材值。

DILLIMAX 690 Welding and flame cutting

Due to its high yield strength, DILLIMAX 690 requires special care during plate processing. For flame cutting, the following minimum preheating temperatures are recommended : 25 °C (77 °F)4) 適用於厚度達 20 毫米(0.8 吋)的板材4), 50 °C (122 °F)4) for plate thickness up to 50 mm (2 in)4), 100°C (212°F)4) for plate thickness up to 100 mm (4 in) 4), 150 °C (302 °F)4) for plate thickness up to 200 mm (8 in)4) and 180 °C (356 °F)4) 對於較厚的板。

For general welding instructions, please consult the EN 1011. In order to ensure that the tensile strength of the weld metal fulfils the requirements of the base metal, the heat input and interpass temperature must be limited during welding. Experience has shown that the welding conditions should be chosen so that the cooling time t8/5 does not exceed 20 seconds. This is applicable when using suitable filler materials of a corresponding yield strength class.

The high yield strength of the base material must be taken into account when choosing the filler materials.

It should be considered that increased heat input leads to lower tensile properties in the weld metal. If a stress relieving heat treatment is planned during or after plate processing, this must also be considered when selecting the filler materials. To avoid hydrogen-induced cold cracking, only filler materials, which add very little hydrogen to the base metal, may be used. Therefore, shielded arc welding should be preferred.

4) The approximately converted values in brackets are for information only.

For manual arc welding, electrodes with basic coating (type HD<5 ml/100 g in accordance with ISO 3690), and dried according to the manufacturer’s instructions, should be used.

DILLIMAX 690 Heat treatment

如果由於結構規定、結構原因或製造需求而必須考慮消除應力,請諮詢我們。結構部件的性能可以透過應力消除熱處理來改變。

技術資訊“中提供了有關火焰切割、焊接、機械加工以及 DILLIMAX 結構特性的詳細說明”使用高強度鋼節省成本 – DILLIMAX”.

一般技術交付要求

除非另有約定,否則適用 EN 10021 的一般技術交付要求。

公差

除非另有約定,公差將符合 EN 10029,厚度為 A 級,最大平面度偏差為表 4,鋼組 H。訂購前可根據要求提供較小的平面度偏差。

表面質量

除非另有約定,規格將符合 EN 10163-2,A2 級。

一般說明

If particular requirements are demanded and not covered in this data sheet, please contact us with the specifications for our review and agreement prior to ordering. The information in this data sheet is a product description.