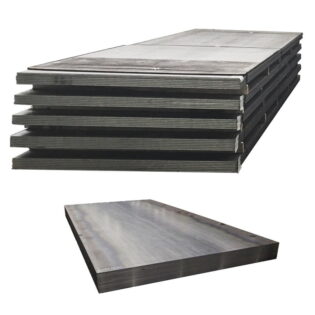

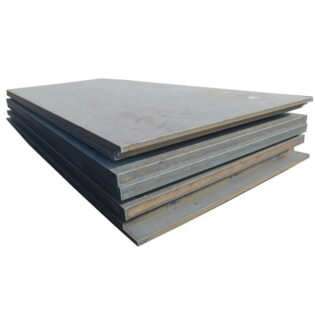

Dillidur 550 Aşınmaya Dayanıklı Çelik Levha

Dillidur 550 is a wear-resistant steel plate with a nominal hardness of 550 HBW in the delivery state.

Dillidur 550 can be used in high-strength wear environments.

Application examples: extremely worn parts of earth-moving machinery, conveying equipment, crushers and waste recycling equipment.

Dillidur 550 Aşınmaya Dayanıklı Çelik Levha

Dillidur 550 is a wear-resistant steel plate with a nominal hardness of 550 HBW in the delivery state.(DILLINGER)

Dillidur 550 can be used in high-strength wear environments.

Application examples: extremely worn parts of earth-moving machinery, conveying equipment, crushers and waste recycling equipment.

Dillidur 550 PDF DOWNLOAD

Supply Size Range

DİLİDUR 550 is available in thicknesses from 10mm (0.4 inches) to 51mm (2 inches) and widths below 3300mm (130 inches) 2 .

Dillidur 550 Chemical Composition:

Based on smelting analysis, the following limit values(%) are applicable to each component

| C | Ve | Mn | P | S |

| ≤ 0.37 | ≤ 0,70 | ≤ 1,60 | ≤ 0,025 | ≤ 0,010 |

Kalınlığa bağlı olarak aşağıdaki alaşım elementlerinden bir veya daha fazlası eklenecektir:

| Ay | İçinde | Cu | CR | V | Not | B |

| ≤ 0,60 | ≤ 1.40 | ≤ 0,30 | ≤ 1,50 | ≤ 0,08 | ≤ 0,05 | ≤ 0,005 |

Erimiş çelik tamamen sakinleştirilir ve ince taneli hale getirilmesi için işlenir.

1 Bu bilgilerin içeriği ürün açıklamasıdır ve zaman zaman güncellenebilir.

2 The conversion value of myopia in parentheses is an offensive reference.

Karbon eşdeğeri referans değeri:

| CEV A | 00,70 |

| CET B | 00,50 |

A CEV =C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

B CET =C+(Mn+Mo)/10+(Cr+Cu)/20+Ni/40

Teslim durumu:

The steel plate is quenched by temperature controlled water or water quenched + tempered.

Teslimat durumundaki mekanik özellikler

Sertlik

Surface Brinell hardness at room temperature: 520-580 HBW

Longitudinal specimen V-notch Charpy impact test (reference value for 20mm thick steel plate):

Charpy darbe enerjisi: -20°C'de (-4°F) 25 J 3

Test

yüzey Brinell sertliği test edildi her fırında ve her 40 tonda bir.

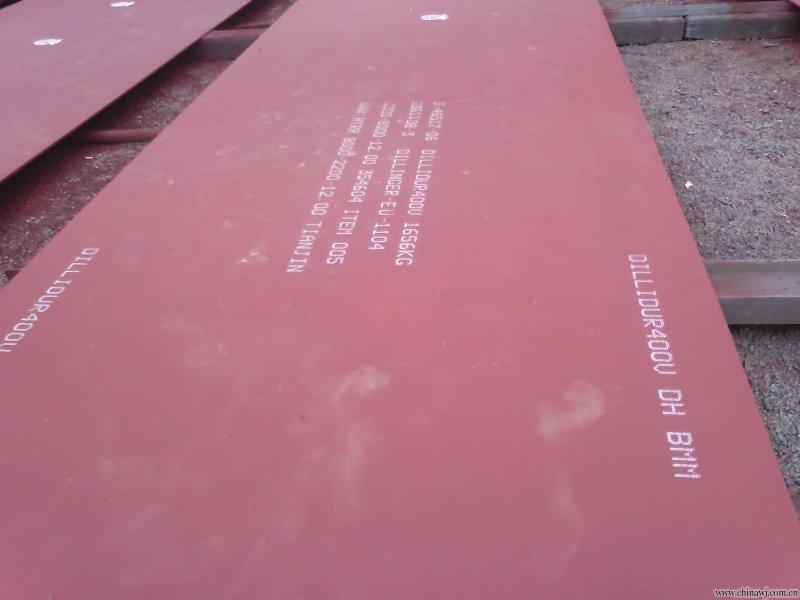

Çelik levha işareti

Başka bir anlaşma yoksa, çelik levha markası en azından aşağıdaki içeriği içerecektir:

- Grade (DILLIDUR 550)

- Fırın numarası

- Anakart numarası ve çelik plaka numarası

- Çelik fabrikası işareti

- Inspection representative label

3 Parantez içindeki neredeyse dönüştürülmüş değerler yalnızca referans amaçlıdır.

Processing performance

The whole set of processing technology and application technology used by the user is very important to the reliability of the product made from this material. It should be ensured that the design, structure and processing method are suitable for this material and meet the latest processing requirements and the purpose of the product that the processor must follow. Purpose requirements. The user should select the material by himself, and fully consider the high strength and high hardness of the material, and follow the process recommendation that meets the national standards for safe production.

Soğuk şekillendirme

Although DILLIDUR 550 is too high in hardness and strength, the room for cold forming is limited, and you must consult in advance.

sertliği hot forming/heat treatment DILLIDUR 550 comes from accelerated cooling from the austenitizing temperature. If the hardness does not decrease significantly after hot forming, it is possible to supplement the subsequent re-quenching treatment. However, the hardness obtained after re-quenching will be different from the hardness tested when the steel plate leaves the factory. This is because the cooling efficiency of the quenching equipment in the processing plant is generally lower than that of the quenching equipment during the production of steel plates.

This material can be heated to about 250°C (482°F) without a significant decrease in hardness.

Flame cutting and welding:

For all thickness steel plates, the following minimum preheating temperature should be followed during flame cutting: 175°C (347°F)

After flame cutting, measures should be taken to maintain slow cooling. For example, insulation wool can be used, which will reduce the risk of hydrogen-induced cracking.

When using ferritic welding consumables, care should be taken to select very low hydrogen content welding consumables and follow the following preheating temperature: 150°C (302°F) for thickness 15mm and below; 200°C (392°F) for thickness above 15mm F)

When using soft austenitic welding consumables, the preheating temperature of 50°C (122°F) is usually sufficient.

In order to avoid the decrease in hardness, the preheating temperature and interlayer temperature corresponding to flame cutting and welding should not exceed 250°C (482°F).

Manual arc welding should use alkaline-coated electrodes with residual moisture in the ground (if necessary, they should be dried according to the requirements of the electrode manufacturer).

İşleme

Despite its extremely high hardness, DILLIDUR 550 can still be machined by using sharp carbide tools. It is necessary to ensure that a heavy-duty processing machine tool is used, and an appropriate feed speed and cutting speed are used.

Genel teslimat teknik gereksinimleri

Aksi kararlaştırılmadıkça genel teslimat teknolojisi EN 10021 standardının kullanılmasını gerektirir.

Hata payı

Aksi kararlaştırılmadıkça tolerans gereklilikleri EN 10029'a atıfta bulunur ve kalınlık A seviyesi için geçerlidir.

Yüzey kalitesi

Aksi kararlaştırılmadıkça EN 10163-2 standardına bakın ve A2 seviyesini uygulayın.

Toplam not

Kullanım amacı veya takip süreci nedeniyle bu belgede yer almayan malzemelere ilişkin başka özel gereksinimler varsa, bunlar siparişten önce müzakere edilebilir.